Product Description

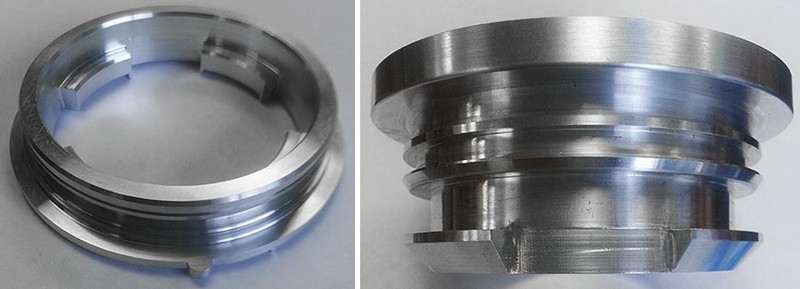

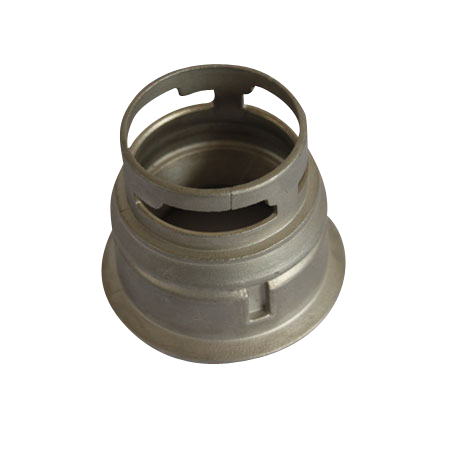

Investment Casting, also known as Lost Wax Casting, is a precision casting process that provides design flexibility and significant cost advantages.

The Investment Casting process involves pouring molten metal into a mold that has been created using a wax model. Once the mold is made, the wax model is melted and drained away.Hollow cores can be effected by using a heat-proof core that prevents the molten metal from totally filling the mold.

Investment Casting is generally used for small castings, but can be used to produce much larger components.

Dimensional tolerances of ± 0.003 in./in. are readily achieved. Delicate parts with walls as thin as 0.025 in. can be achieved by investment casting.

Gráid Ábhair Choitianta Réitigh Cruach Dhosmálta

SS304: Is féidir tagairt a dhéanamh don chruach austeníte is mó a úsáidtear mar dhosmálta A2.

SS316: An dara cruach austenite is coitianta, ar a dtugtar cruach dhosmálta A4 freisin. Úsáidtear SS316 go príomha mar gheall ar a fhriotaíocht mhéadaithe i gcoinne creimeadh.

SS304L & SS316L (superaustenitic stainless steel): The [L” means that the carbon content of the alloy is below 0.03%, which reduces the sensitization effect caused by the high temperatures involved in welding. Compare with 300 series, it shows better resistance to stress-corrosion cracking.

17-4 PH: An cruach dhosmálta martensíteach is coitianta a chruasaíonn deascadh, a úsáideann thart ar 17% cróimiam agus 4% nicil.

Surface Treatments of Réitigh Cruach Dhosmáltas

Pléascadh LámhaighÚsáidtear é chun craiceann ocsaíd dhubh dromchla a bhaint tar éis táirgí cruach dhosmálta a chaitheamh.

Cóireáil Picilte & Pasúcháin: Pickling is a chemical treatment way to eliminate surface dirts like oxide skin, rust, welding spots,ect. And passivation is a process that forming a new abundant chromium protective layer, thus to improve the anti-oxidation ability of stainless steel castings.

Leictrea-snasúÚsáidtear é chun burrs beaga bídeacha dromchla a bhaint agus gile teilgin cruach dhosmálta a fheabhsú.

Snasú ScátháinBealach snasta dromchla: Cineál snasta dromchla ar féidir leis dromchla réidh agus lonrach cosúil le bailchríoch scátháin a bhaint amach.

Feidhmiú Réitigh Cruach Dhosmálta

Mar gheall ar airíonna fisiceacha uathúla cruach dhosmálta, úsáidtear teilgin cruach dhosmálta i raon leathan tionscal, go háirithe iad siúd atá i dtimpeallachtaí diana. Seo a leanas príomhfheidhmeanna teilgin cruach dhosmálta

ár monarcha