Product Description

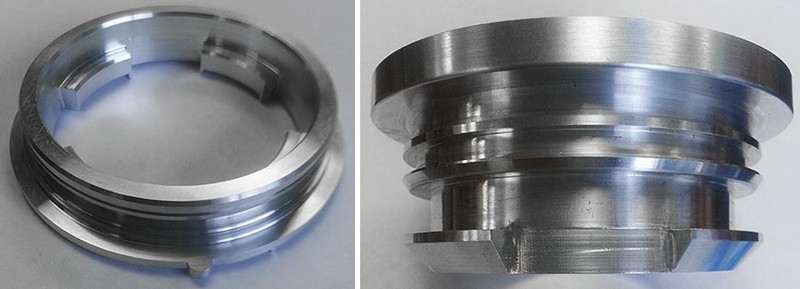

Investment Casting, also known as Lost Wax Casting, is a precision casting process that provides design flexibility and significant cost advantages.

The Investment Casting process involves pouring molten metal into a mold that has been created using a wax model. Once the mold is made, the wax model is melted and drained away.Hollow cores can be effected by using a heat-proof core that prevents the molten metal from totally filling the mold.

Investment Casting is generally used for small castings, but can be used to produce much larger components.

Dimensional tolerances of ± 0.003 in./in. are readily achieved. Delicate parts with walls as thin as 0.025 in. can be achieved by investment casting.

Almindelige materialekvaliteter af Rustfrit stålstøbning

SS304: Det mest anvendte austenitstål kan betegnes som A2 rustfrit stål.

SS316: Det næstmest almindelige austenitstål, også kaldet A4 rustfrit stål. SS316 anvendes primært på grund af sin øgede korrosionsbestandighed.

SS304L og SS316L (superaustenitic stainless steel): The [L” means that the carbon content of the alloy is below 0.03%, which reduces the sensitization effect caused by the high temperatures involved in welding. Compare with 300 series, it shows better resistance to stress-corrosion cracking.

17-4 PH: Det mest almindelige udfældningshærdende martensitiske rustfrie stål, der bruger omkring 17% krom og 4% nikkel.

Surface Treatments of Rustfrit stålstøbnings

KugleblæsningBruges til at fjerne sort oxidhud på overfladen efter støbning af rustfri stålprodukter.

Bejdsning og passiveringsbehandling: Pickling is a chemical treatment way to eliminate surface dirts like oxide skin, rust, welding spots,ect. And passivation is a process that forming a new abundant chromium protective layer, thus to improve the anti-oxidation ability of stainless steel castings.

ElektropoleringBruges til at fjerne små grater på overfladen og forbedre lysstyrken på støbegods i rustfrit stål.

SpejlpoleringEn form for overfladepolering, der kan opnå en glat og skinnende overflade som en spejlblank finish.

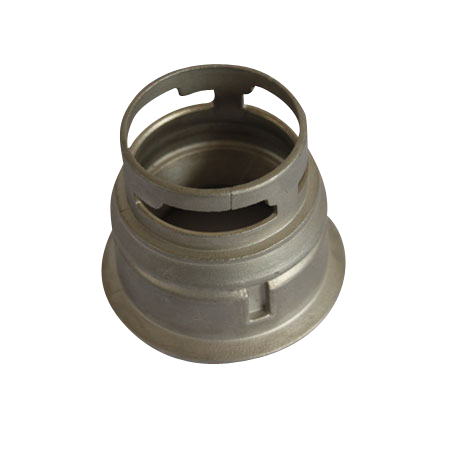

Anvendelse af støbegods i rustfrit stål

På grund af de unikke fysiske egenskaber ved rustfrit stål anvendes støbegods i rustfrit stål i en bred vifte af industrier, især dem, der udføres i barske miljøer. Nedenfor er de vigtigste anvendelser af støbegods i rustfrit stål.

vores fabrik