Product Description

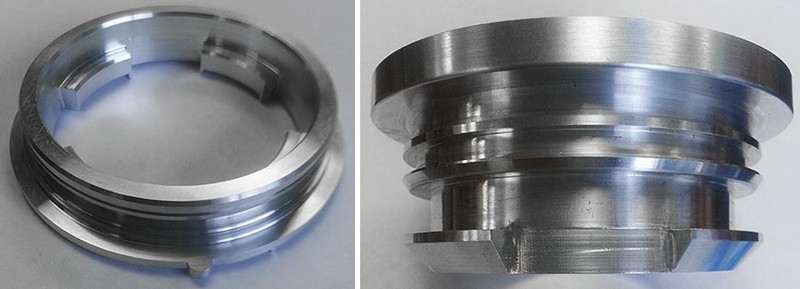

Investment Casting, also known as Lost Wax Casting, is a precision casting process that provides design flexibility and significant cost advantages.

The Investment Casting process involves pouring molten metal into a mold that has been created using a wax model. Once the mold is made, the wax model is melted and drained away.Hollow cores can be effected by using a heat-proof core that prevents the molten metal from totally filling the mold.

Investment Casting is generally used for small castings, but can be used to produce much larger components.

Dimensional tolerances of ± 0.003 in./in. are readily achieved. Delicate parts with walls as thin as 0.025 in. can be achieved by investment casting.

Gradus Materialium Communium Fusio Chalybis Inoxidabilis

SS304: Chalybs austeniticus latissime adhibitus, fortasse chalybs inoxidabilis A2 appellari potest.

SS316: Secunda chalybs austenita vulgatissima, etiam chalybs inoxidabilis A4 appellata, SS316 imprimis propter auctam resistentiam corrosionis adhibetur.

Inoxidabilis 304L et Inoxidabilis 316L (superaustenitic stainless steel): The [L” means that the carbon content of the alloy is below 0.03%, which reduces the sensitization effect caused by the high temperatures involved in welding. Compare with 300 series, it shows better resistance to stress-corrosion cracking.

17-4 PH: Frequentissima chalybs inoxidabilis martensitica praecipitatione durissima, quae circiter 17% chromii et 4% niccoli utitur.

Surface Treatments of Fusio Chalybis Inoxidabiliss

Iaculatio IaculatoriaAdhibetur ad removendam superficiem nigri oxidi post fusuram productorum chalybis inoxidabilis.

Decaptatio et Passivatio: Pickling is a chemical treatment way to eliminate surface dirts like oxide skin, rust, welding spots,ect. And passivation is a process that forming a new abundant chromium protective layer, thus to improve the anti-oxidation ability of stainless steel castings.

ElectropolituraAdhibetur ad minimas bavas superficiales removendas et splendorem fusorum chalybis inoxidabilis augendum.

Politura SpeculiGenus poliendi superficiem qua superficiem lenem et nitentem, instar speculi, consequi potest.

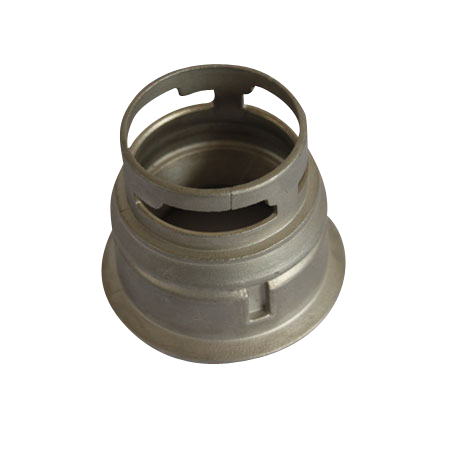

Applicatio Fusurarum Chalybis Inoxidabilis

Ob proprietates physicas singulares chalybis inoxidabilis, fusiones chalybis inoxidabilis in amplam varietatem industriarum, praesertim in iis quae in condicionibus severis versantur, adhibentur. Infra sunt usus principales fusionis chalybis inoxidabilis.

officina nostra