Product Description

Cruach Dhosmálta is cóimhiotal cruach é ina bhfuil cion cróimiam 10.5% ar a laghad de réir maise. Úsáidtear cruach dhosmálta i gcás ina bhfuil airíonna an chruach agus an dá rud friotaíocht creimeadh Mar sin, cosúil le cóimhiotail chruach teilgthe eile, úsáidtear cruach dhosmálta go forleathan le haghaidh táirgeadh réitigh.

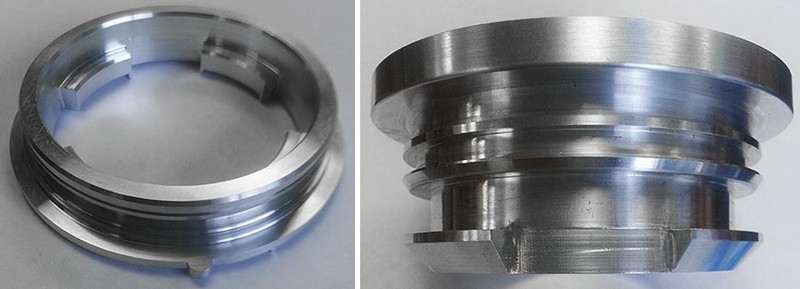

Déantar réitigh cruach dhosmálta inár dteilgcheárta cruach den chuid is mó trí réitigh shilice sol próiseas. Is é réitigh shilice sol an ceann is mó réitigh infheistíochta beachtais process. Stainless steel casting process involves melting of metal, molding, and creating quality components with constant heating or cleaning. When normal casting components are not able to deliver enough strength and shock resistant features then stainless steel castings are just taken wonderful choice over others. This process can produce high precision net shape castings with no machining. Normally we can control such precision stainless steel casting with tolerance CT5-6 level. Another advantage is that, with this process, our foundry can supply stainless steel casting with no defects.

Gráid Ábhair Choitianta Réitigh Cruach Dhosmálta

SS304: Is féidir tagairt a dhéanamh don chruach austeníte is mó a úsáidtear mar dhosmálta A2.

SS316: An dara cruach austenite is coitianta, ar a dtugtar cruach dhosmálta A4 freisin. Úsáidtear SS316 go príomha mar gheall ar a fhriotaíocht mhéadaithe i gcoinne creimeadh.

SS304L & SS316L (superaustenitic stainless steel): The [L” means that the carbon content of the alloy is below 0.03%, which reduces the sensitization effect caused by the high temperatures involved in welding. Compare with 300 series, it shows better resistance to stress-corrosion cracking.

17-4 PH: An cruach dhosmálta martensíteach is coitianta a chruasaíonn deascadh, a úsáideann thart ar 17% cróimiam agus 4% nicil.

Cóireálacha Dromchla ar Réitigh Cruach Dhosmálta

Pléascadh LámhaighÚsáidtear é chun craiceann ocsaíd dhubh dromchla a bhaint tar éis táirgí cruach dhosmálta a chaitheamh.

Cóireáil Picilte & Pasúcháin: Pickling is a chemical treatment way to eliminate surface dirts like oxide skin, rust, welding spots,ect. And passivation is a process that forming a new abundant chromium protective layer, thus to improve the anti-oxidation ability of stainless steel castings.

Leictrea-snasúÚsáidtear é chun burrs beaga bídeacha dromchla a bhaint agus gile teilgin cruach dhosmálta a fheabhsú.

Snasú ScátháinBealach snasta dromchla: Cineál snasta dromchla ar féidir leis dromchla réidh agus lonrach cosúil le bailchríoch scátháin a bhaint amach.

Feidhmiú Réitigh Cruach Dhosmálta

For the unique physical properties of stainless steel, Stainless steel castings are served for a wide range of industries, especially those in severe environments. Below are the main applications of stainless steel casting

ár monarcha