Products

-

Cast copper flange

product presentation :

Flange also called flange or flange.A part that interconnects a pipe to a pipe, connected to a pipe end.There are holes in the flange and the bolts fasten the two flanges together.Gasket between flanges.Flange is a kind of disk, in the pipeline engineering most common, flanges are used in pairs.In piping engineering, flanges are mainly used for piping connections.Install one flange at each end of the two pipes. The low-pressure pipes can be connected with wire flange. Welding flange is used for the pressure of more than 4kg.Place a gasket between the two flanges and bolt them down.

Flanges of different pressure have different thickness and use different bolts.

Pumps and valves, when connected to the pipe, the parts of these equipment are also made into the corresponding flange shape, also known as the flange connection.

General in two planes at the periphery of the use of bolts and closed connection parts, are generally called "flange", such as the ventilation pipe connection, this kind of parts can be called "flange part".

Threaded flange is a kind of flange.The threaded flange connection structure is an assembly, which is composed of a pair of flanges, several bolts, nuts and a gasket.

Product Introduction:

1/2"--30" threaded flange

Chinese standards:

HG5051 ~ 5028-58, HG20592 ~ 20605-97, 20615 ~ 20326-97

HGJ44 ~ 68-91, SH3406-92, SH3406-96

Shj406-89, SHT501-97, SYJS3-1-1 ~ 5

JB81 ~ 86-59, JB/T81 ~ 86-94, JB577-64

Jb577-79, JB585-64, JB585-79

JB1157 ~ 1164-82, JB2208-80, JB4700 ~ 4707-92

Jb4721-92, DG0500 ~ 0528, 0612 ~ 0616

GD0500 ~ 0528, GB9112 ~ 9125-88, GB/T13402-92 -

Manhole covers

product presentation :

Good toughness.The impact value is similar to that of medium carbon steel, which is more than 10 times of gray iron material.

Strong corrosion resistance.In the water spray corrosion test, the corrosion amount in 90 days is only 1/40 of that of steel pipe and 1/10 of that of gray iron pipe.The service life is 2 times of gray iron pipe and 5 times of ordinary steel pipe.

Good plasticity.Elongation ≥7%, similar to high carbon steel, but gray iron material elongation is zero.

High strength.The tensile strength ob ≥420MPa and yield strength OS ≥300MPa are the same as low carbon steel and three times as gray iron material.

Because of its nodular graphite microstructure, ductile iron is better than cast steel in reducing vibration capacity, so it is more beneficial to reduce stress.An important reason for choosing ductile iron is that ductile iron costs less than cast steel.The low cost of ductile iron makes this material more popular, more efficient, and less costly to machine.

The strength of ductile iron is comparable to that of cast steel.Ductile iron has a higher yield strength, with a minimum yield strength of 40K and cast steel yield strength of only 36K.Ductile iron is more resistant to corrosion and oxidation than cast steel in most municipal applications such as water, salt water, steam, etc.

-

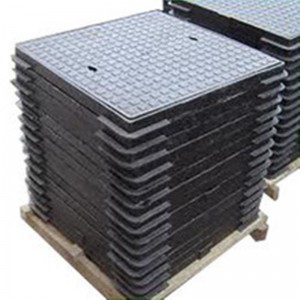

Cast iron manhole covers

product presentation :

Good toughness.The impact value is similar to that of medium carbon steel, which is more than 10 times of gray iron material.

Strong corrosion resistance.In the water spray corrosion test, the corrosion amount in 90 days is only 1/40 of that of steel pipe and 1/10 of that of gray iron pipe.The service life is 2 times of gray iron pipe and 5 times of ordinary steel pipe.

Good plasticity.Elongation ≥7%, similar to high carbon steel, but gray iron material elongation is zero.

High strength.The tensile strength ob ≥420MPa and yield strength OS ≥300MPa are the same as low carbon steel and three times as gray iron material.

Because of its nodular graphite microstructure, ductile iron is better than cast steel in reducing vibration capacity, so it is more beneficial to reduce stress.An important reason for choosing ductile iron is that ductile iron costs less than cast steel.The low cost of ductile iron makes this material more popular, more efficient, and less costly to machine.

The strength of ductile iron is comparable to that of cast steel.Ductile iron has a higher yield strength, with a minimum yield strength of 40K and cast steel yield strength of only 36K.Ductile iron is more resistant to corrosion and oxidation than cast steel in most municipal applications such as water, salt water, steam, etc.

-

Custom grates

product presentation:

Grizzley grates are a group of cast-iron grates used to cover grates, pits, and other protective grates that protect a person's safety or protect trees and other protective elements from damage.

The gratings are rain gratings, tree gratings, grate gratings, floor gratings, etc.For example, iron grates are often placed on the drains of bathhouses, allowing water to flow in and preventing foot and foot injuries.

-

Resin covers

product presentation :

1. Strong anti-theft performance: resin composite material manhole cover using unsaturated resin, glass fiber and other material and reinforced skeleton compounded by the special production process, after high temperature and press for a forming, material recycling value, it is very difficult to remove the steel bar (take out the value of steel costs more than steel) so it is of active anti-theft function.

2. Large bearing capacity: the bottom of the special pot bottom structure, so that the stressed area increased ten times or even dozens of times.The continuous reinforcement fiber is used to ensure the fiber fiber and glass fiber cloth are integrated in the material, so that the product has sufficient carrying capacity.And meet or exceed national standards.

3. Long service life, through the adoption of high performance resin, glass fiber and special formula, production process to ensure that the penetration of resins in glass fiber, greatly enhanced the stick relay, make the material under cyclic loading, do not produce internal damage, so as to ensure the service life of the product, and other resin composite manhole cover with the same advantages.Put an end to the drawbacks of poor adhesion.

4. Beautiful and practical, high grade: According to the needs of high-end customers, we can make a complex LOGO and a variety of colors on the same manhole cover surface of personalized design, so that the pattern is delicate, bright colors, distinct.And can be made according to customer demand and all kinds of stone pavement the same imitation stone surface and color.

5. High/low temperature resistance, good insulation and strong corrosion resistance: corrosion resistance, non-toxic and harmless.No metal additives, played a real sense of insulation effect.It can be used in complex, changeable, harsh and demanding places.The products have been tested by the relevant national authoritative testing institutions, with obvious acid and alkali resistance, corrosion resistance, anti-aging and other indicators have reached and exceeded the national standards.

6. Environmental protection, anti-skid, low noise: the product will not slip, no harsh noise and reverse phenomenon after the vehicle is run over.At the same time, due to the light weight of the product, cover, seat buckle precision, overcome other inspection cover "jump, stilt, sound, displacement" and other problems.

-

Custom flange

product presentation :

Flange also called flange or flange.A part that interconnects a pipe to a pipe, connected to a pipe end.There are holes in the flange and the bolts fasten the two flanges together.Gasket between flanges.Flange is a kind of disk, in the pipeline engineering most common, flanges are used in pairs.In piping engineering, flanges are mainly used for piping connections.Install one flange at each end of the two pipes. The low-pressure pipes can be connected with wire flange. Welding flange is used for the pressure of more than 4kg.Place a gasket between the two flanges and bolt them down.

Flanges of different pressure have different thickness and use different bolts.

Pumps and valves, when connected to the pipe, the parts of these equipment are also made into the corresponding flange shape, also known as the flange connection.

General in two planes at the periphery of the use of bolts and closed connection parts, are generally called "flange", such as the ventilation pipe connection, this kind of parts can be called "flange part".

Threaded flange is a kind of flange.The threaded flange connection structure is an assembly, which is composed of a pair of flanges, several bolts, nuts and a gasket.

Product Introduction:

1/2"--30" threaded flange

Chinese standards:

HG5051 ~ 5028-58, HG20592 ~ 20605-97, 20615 ~ 20326-97

HGJ44 ~ 68-91, SH3406-92, SH3406-96

Shj406-89, SHT501-97, SYJS3-1-1 ~ 5

JB81 ~ 86-59, JB/T81 ~ 86-94, JB577-64

Jb577-79, JB585-64, JB585-79

JB1157 ~ 1164-82, JB2208-80, JB4700 ~ 4707-92

Jb4721-92, DG0500 ~ 0528, 0612 ~ 0616

GD0500 ~ 0528, GB9112 ~ 9125-88, GB/T13402-92 -

Steel pipi flange

product presentation :

Flange also called flange or flange.A part that interconnects a pipe to a pipe, connected to a pipe end.There are holes in the flange and the bolts fasten the two flanges together.Gasket between flanges.Flange is a kind of disk, in the pipeline engineering most common, flanges are used in pairs.In piping engineering, flanges are mainly used for piping connections.Install one flange at each end of the two pipes. The low-pressure pipes can be connected with wire flange. Welding flange is used for the pressure of more than 4kg.Place a gasket between the two flanges and bolt them down.

Flanges of different pressure have different thickness and use different bolts.

Pumps and valves, when connected to the pipe, the parts of these equipment are also made into the corresponding flange shape, also known as the flange connection.

General in two planes at the periphery of the use of bolts and closed connection parts, are generally called "flange", such as the ventilation pipe connection, this kind of parts can be called "flange part".

Threaded flange is a kind of flange.The threaded flange connection structure is an assembly, which is composed of a pair of flanges, several bolts, nuts and a gasket.

Product Introduction:

1/2"--30" threaded flange

Chinese standards:

HG5051 ~ 5028-58, HG20592 ~ 20605-97, 20615 ~ 20326-97

HGJ44 ~ 68-91, SH3406-92, SH3406-96

Shj406-89, SHT501-97, SYJS3-1-1 ~ 5

JB81 ~ 86-59, JB/T81 ~ 86-94, JB577-64

Jb577-79, JB585-64, JB585-79

JB1157 ~ 1164-82, JB2208-80, JB4700 ~ 4707-92

Jb4721-92, DG0500 ~ 0528, 0612 ~ 0616

GD0500 ~ 0528, GB9112 ~ 9125-88, GB/T13402-92 -

Custom forged parts

product presentation:

The forging machine is used to produce plastic deformation by exerting pressure on the metal blank to obtain the forging with certain mechanical properties, shape and size.Through the continuous hammering of pipe fitting, the original segregation, porosity, porosity, slag and other compaction and bonding in the ingot become more compact, and the plastic and mechanical properties of the metal are improved.Forging pipe fittings mainly includes forging flange, forging reducing pipe, forging tee, etc.The main materials of forged pipe fittings are Q235, Q345, 16Mn,20#,35#,45#,40Cr,12Cr1MoV, 30CrMo,15CrMo, 20G, etc.With corresponding forging fittings is casting fitting, the mechanical properties of castings below forgings with the same material mechanical properties, casting pipe fittings metal melting into complying with the requirements of a certain liquid and poured into the mold, after cooling solidification, men get a predetermined shape, size and performance of the casting parts (or blank) process.[1]

-

Forging steel pipe

product presentation:

The forging machine is used to produce plastic deformation by exerting pressure on the metal blank to obtain the forging with certain mechanical properties, shape and size.Through the continuous hammering of pipe fitting, the original segregation, porosity, porosity, slag and other compaction and bonding in the ingot become more compact, and the plastic and mechanical properties of the metal are improved.Forging pipe fittings mainly includes forging flange, forging reducing pipe, forging tee, etc.The main materials of forged pipe fittings are Q235, Q345, 16Mn,20#,35#,45#,40Cr,12Cr1MoV, 30CrMo,15CrMo, 20G, etc.With corresponding forging fittings is casting fitting, the mechanical properties of castings below forgings with the same material mechanical properties, casting pipe fittings metal melting into complying with the requirements of a certain liquid and poured into the mold, after cooling solidification, men get a predetermined shape, size and performance of the casting parts (or blank) process.[1]