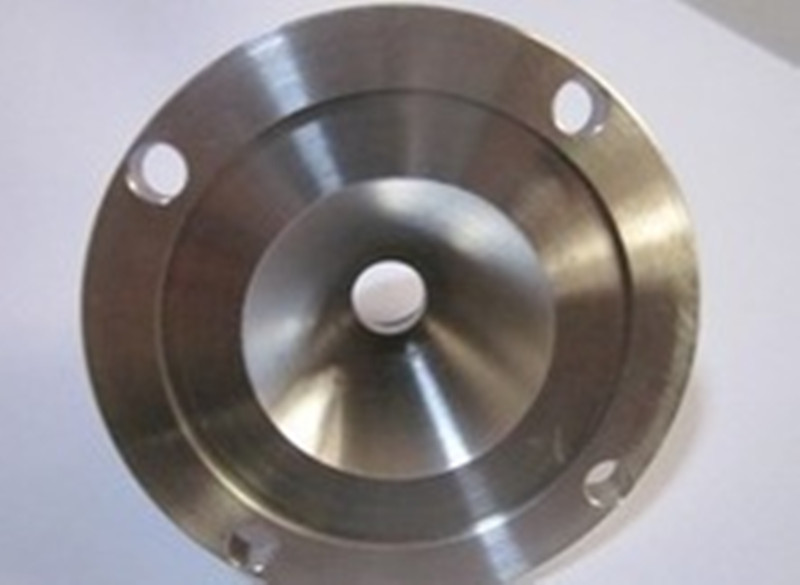

OEM Customized Stainless Steel Forging Ring

Product Description

Forging is a cost effective manufacturing process for high quantity runs it is also used for items that require the grain structure/ mechanical properties resulting from the forging process. Forging is limited to products of fairly simple design, generally without under cuts and sharp edges. Tooling costs for forging are higher than that of investment casting and sand casting. Drop forging offers good tolerances . Surface finish of drop forging is also ok but signs of the flash line may be visible.

Forging:

1. development of grain flow leads to increased product strength.

2. materials are generally less expensive than the materials required for casting.

3. Limited scrap and rework. Reduced labor costs.

4. consistent ductility, known yields, and increased strength due to grain development.