OEM Customized Precision Investment Casting

Product Description

Investment casting can make use of most metals, most commonly using aluminum alloys, bronze alloys, magnesium alloys, cast iron, stainless steel, and tool steel.

This process is beneficial for casting metals with high melting temperatures that can not be molded in plaster or metal. Parts that are typically made by investment casting include those with complex geometry such as turbine blades or firearm components. High temperature applications are also common, which includes parts for the automotive, aircraft, and military industries.

Investment casting requires the use of a metal die, wax, ceramic slurry, furnace, molten metal, and any machines needed for sandblasting, cutting, or grinding.

Products description

Process:Investment Casting

Material:Stainless Steel,Carbon Steel,Alloy Steel,etc

Weight: 0.001Kg~30Kg

Surface Roughness :UpTo Ra1.6~Ra6.3

Heat Treatment: Anneal,Quenching,Normalizing,Carburizing,Polishing,Plating, Painting,etc

Machining Equipment: CNC Center , CNC Machines, Turning Machines,Drilling Machines , Milling Machines, Grinding Machines,etc

QC System: 100% Inspection Before Shipment

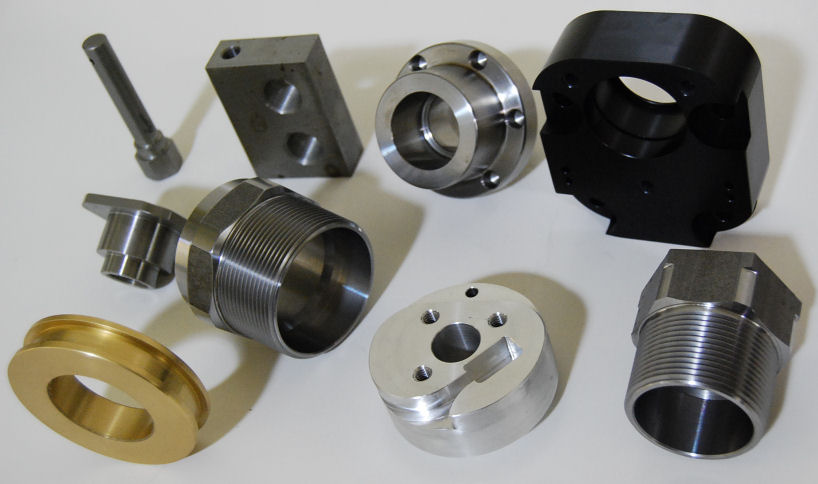

Products show