OEM Custom Stainless Steel Investment Casting Parts

Product Description

Lost wax investment casting allows us to produce metal parts as small as 2 oz. and as large as 100 lbs., in a wide range of ferrous and non-ferrous alloy and with exceptional dimensional accuracy.

The lost wax casting process produces near-net-shape precision metal parts that often require little to no additional machining. The resulting finish is also much better than what is achievable through most other processes. And, the strength and durability of cast metal parts makes them ideal for high wear applications requiring millions of cycles.

Whether we`re casting small metal parts in carbon steel or large, intricate shapes in specialty non-ferrous alloys, we can deliver precision metal cast parts that perfectly match your designs. We offer design assistance, as needed, to help improve both your part`s function and its manufacturability. From the simplest shape to the most complex geometry, we can turn your designs into reality.

Request a quote on lost wax investment casting for your small-to-large precision metal parts, or contact us for more information.

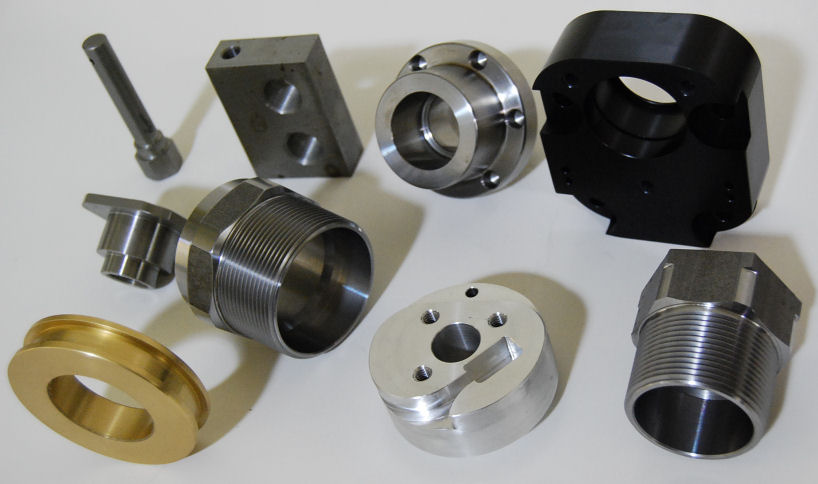

Products show

Process

Our factory