Casting Part is a key solution in the manufacturing industry, specifically within Fabricated metal products and Casting manufacturing. This article explores how Hebei Mingda International Trading Company. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

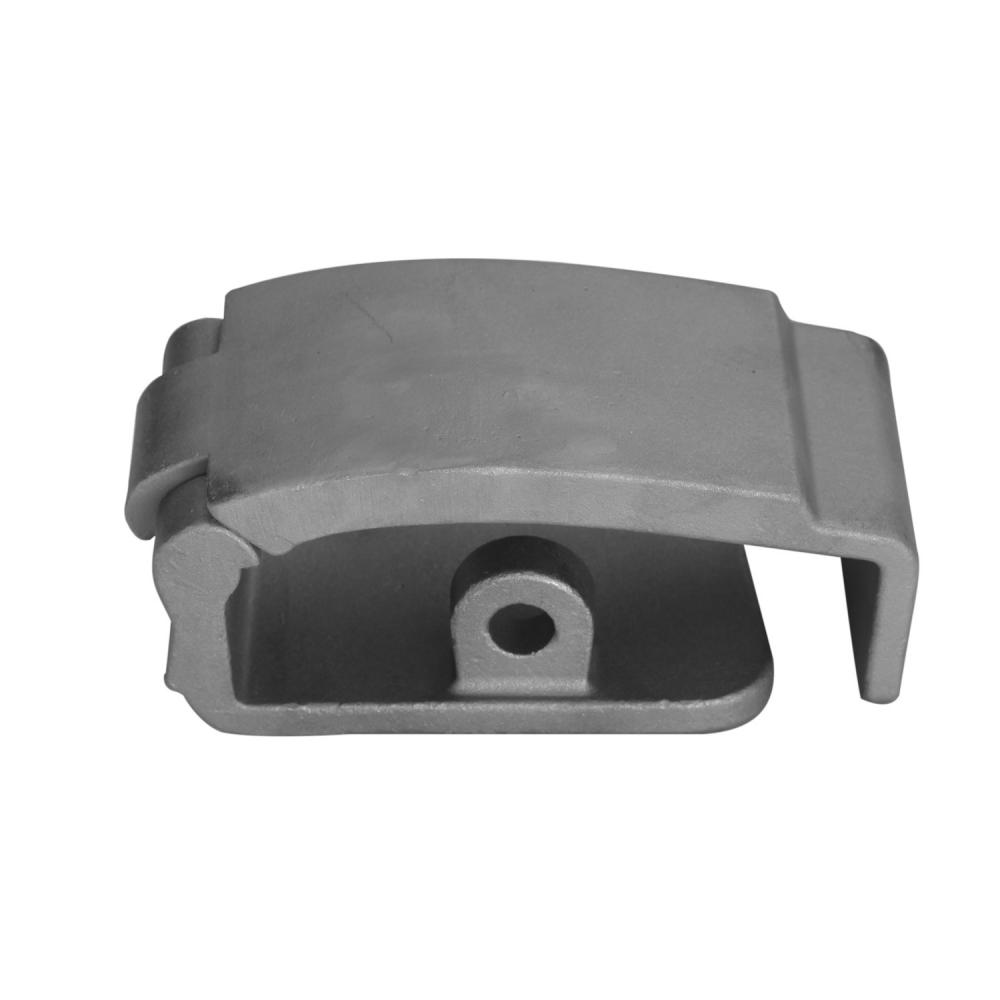

A Casting Part is a precision metal component produced by pouring molten metal into a mold to achieve near-net-shape geometry. In the fabricated metal products sector, casting enables complex internal passages, tight tolerances, and superior repeatability that would be costly or impossible to machine from solid bar. Hebei Mingda International Trading Company. supplies stainless steel, carbon steel, alloy steel, ductile iron, and aluminum Casting Parts using investment (lost-wax), sand, and shell casting, followed by CNC machining and finishing.

Casting Parts are essential across valves and pumps, power transmission, agricultural machinery, rail components, food equipment, and general industrial assemblies. As a trusted producer of China valve casting parts, Hebei Mingda manufactures bodies, bonnets, impellers, and precision seats in stainless steel grades (e.g., 304/316/CF8M) to meet corrosion and pressure requirements. For high-accuracy geometries, a wax Casting Part (investment casting) delivers thin walls, sharp details, and excellent repeatability that slash secondary operations.

Total cost of ownership for a Casting Part hinges on process fit, alloy choice, annual volume, machining allowance, and test requirements. Investment casting typically commands a higher piece price than sand casting but reduces machining, assembly, and scrap—often delivering a lower TCO for complex geometries. Buyers should consider tooling amortization, packaging, logistics, and inspection scope alongside unit price for a true ROI picture.

Sustainability in casting is advancing through higher recycled metal content, energy-efficient melting, optimized gating to boost yield, and water-based binders. Digital simulation reduces trial pours and scrap, cutting both cost and carbon. As regulations tighten around traceability and environmental impact, buyers increasingly request lifecycle data, RoHS/REACH compliance, and greener packaging for every Casting Part sourced globally.

A high-quality Casting Part brings complex geometry, reliability, and cost efficiency to fabricated metal products and casting manufacturing. Hebei Mingda International Trading Company. combines process expertise, rigorous quality control, and responsive support—from tool design to machining and inspection—to reduce risk and accelerate programs for B2B buyers. Explore options for China valve casting parts or request a casting parts pricelist to benchmark your current spend.