Casting Part is a key solution in the manufacturing industry, specifically within Fabricated metal products and Casting manufacturing. This article explores how Hebei Mingda International Trading Company. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

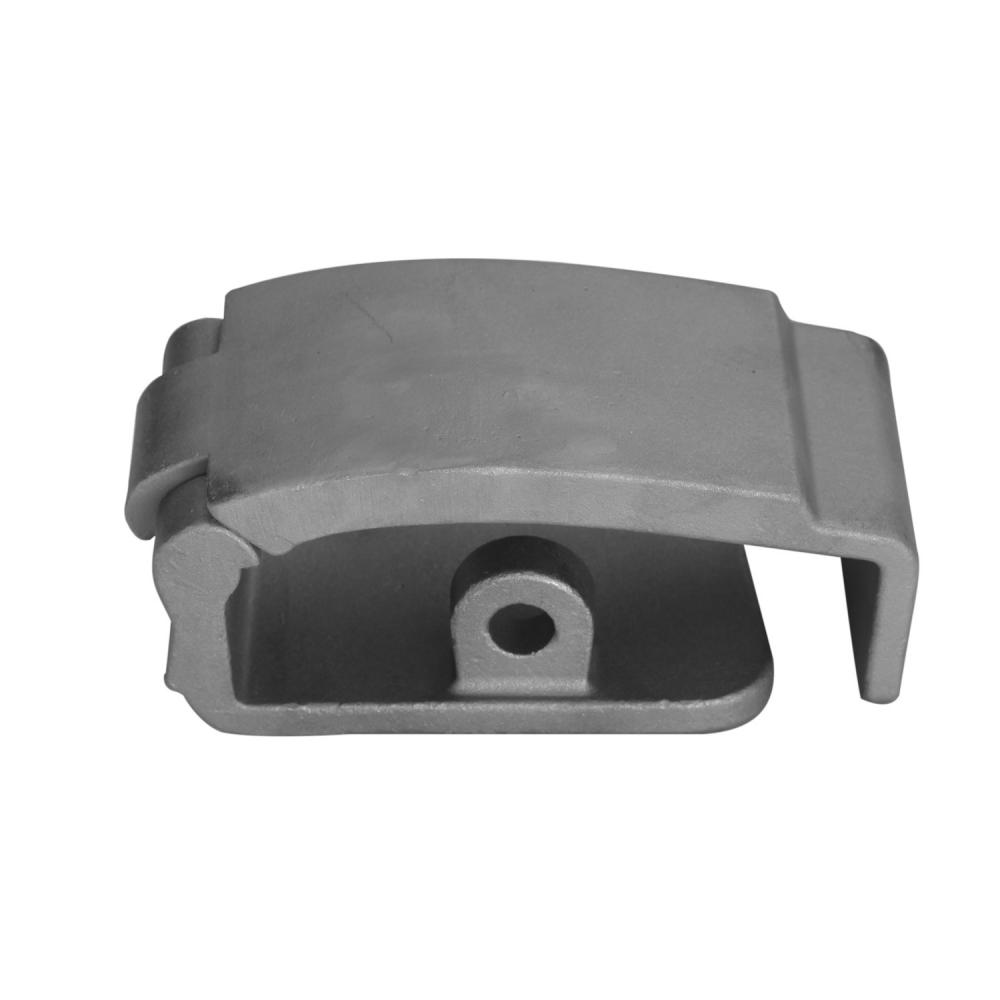

In modern fabricated metal products, a casting part is a precision-formed metal component created by pouring molten metal into a mold. Depending on performance requirements, methods such as investment (lost-wax) casting, sand casting, and die casting are used to achieve complex geometries, consistent wall thickness, and reliable mechanical properties. Stainless steel casting parts are favored across industries for their corrosion resistance, hygiene, and strength-to-weight ratio—qualities that are critical in fluid handling, power transmission, food processing, and general industrial equipment.

Hebei Mingda International Trading Company. supplies OEM/ODM custom stainless steel casting components built for repeatability and lifecycle value. Typical deliverables include housings, impellers, brackets, valve bodies, pump parts, and precision connectors. With investment casting, near-net-shape capability reduces secondary machining, while robust process controls—material verification, dimensional inspection, and surface finishing—support consistent quality. For B2B decision makers evaluating a reliable partner, Hebei Mingda’s project management and coordinated foundry network in China help align tooling design, production scalability, and delivery milestones with your manufacturing plans.

In casting manufacturing, precision components unlock design freedom and cost efficiency. Common applications include pump and China valve casting parts, automation brackets, food-grade fittings, marine hardware, and energy-sector linkages where stainless alloys withstand corrosion and thermal cycling. Investment casting excels for intricate internal passages and smooth surfaces, enabling better flow dynamics in valve and pump bodies and reducing post-processing demands. For end users, that means lighter assemblies, optimized performance, and lower total manufacturing costs.

Hebei Mingda International Trading Company. brings practical advantages to B2B programs: design-for-casting guidance, rapid sampling, and flexible production volumes tied to realistic lead times. Their OEM/ODM capability supports custom alloys, tailored heat treatment, and application-specific surface finishing. Competitive strengths include stable dimensional repeatability, material traceability, and a transparent casting parts pricelist based on geometry, alloy, and quality requirements. For buyers comparing options, the company’s experience with valve-grade stainless components and wax casting part pricelist structures streamlines sourcing decisions and shortens time to qualification.

Total cost of ownership for a casting part is shaped by tooling, alloy selection, dimensional tolerance, and finishing or testing (e.g., NDT, pressure tests). Investment casting typically lowers downstream spend by minimizing machining, scrap, and assembly time. When comparing a casting parts pricelist, consider TCO drivers: tooling amortization across forecast volumes, yield improvements via optimized gating, and the value of near-net-shape over the product lifecycle. Hebei Mingda collaborates early on manufacturability so buyers can balance part performance with realistic budgets and ROI.

Maintenance requirements for end users are generally low when metallurgy and finishing align with the operating environment. In the fabricated metal products sector, customers report smoother commissioning, fewer fit-up issues, and consistent surface integrity when switching to precision-cast alternatives. Buyers also appreciate clear wax casting part pricelist breakdowns that separate tooling, piece price, and optional inspections, making it easier to justify investment and monitor savings as volumes scale. Hebei Mingda’s responsive communication and traceable QC data further enhance the user experience across qualification, ramp-up, and repeat orders.

The casting industry is advancing toward lower emissions, higher recycled content, and tighter compliance with global regulations such as REACH and RoHS. Foundries increasingly leverage recycled steel and optimized melting practices, while engineering teams prioritize weight reduction and design-to-cast strategies to cut energy and material usage. Lifecycle perspectives—durability, reparability, and end-of-life recyclability—now influence sourcing alongside price and lead time, especially for fluid-handling and industrial automation components.

Hebei Mingda International Trading Company. aligns with these market trends by promoting alloys and processes that reduce waste, encouraging early collaboration to eliminate unnecessary machining, and offering surface treatments that extend service life. Their approach helps B2B buyers meet corporate ESG targets without compromising performance or budget. As demand grows for high-integrity China valve casting parts and corrosion-resistant stainless components, Mingda’s forward-thinking material selection, efficient shell-building and burnout practices, and transparent traceability position them as an eco-conscious partner for long-term growth.

From pump and valve bodies to precision brackets and housings, a casting part delivers dependable performance, manufacturability, and lifecycle value in fabricated metal products and casting manufacturing. Hebei Mingda International Trading Company. combines OEM/ODM flexibility with meticulous quality control and clear pricing to support confident B2B sourcing and stable production. Ready to evaluate a project or request a quotation? Contact us: email: liyanhui@bestcastings.cn. Visit our website: https://www.mingdametals.com.