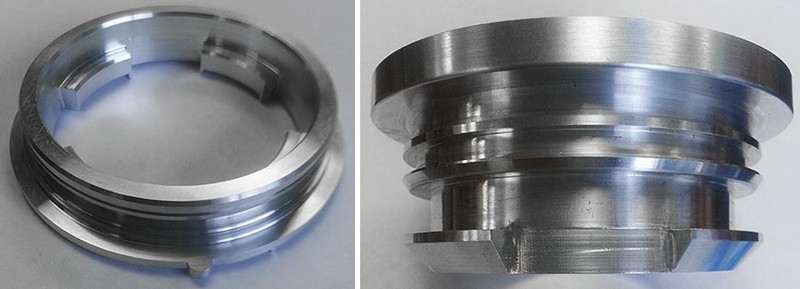

Product Description

Chalybs Inoxidabilis est mixtura chalybis cum minimo 10.5% chromii contento secundum massam. Chalybs inoxidabilis adhibetur ubi et proprietates chalybis et resistentia corrosionis requiruntur. Ita sicut aliae mixturae chalybis fusi, chalybs inoxidabilis late ad productionem fusam adhibetur.

Fusio chalybis inoxidabilis in officina nostra facta praecipue fit a fusura solis silicalis processus. Fusio solis silicae est maxime fusurae periculi accuratae process. Stainless steel casting process involves melting of metal, molding, and creating quality components with constant heating or cleaning. When normal casting components are not able to deliver enough strength and shock resistant features then stainless steel castings are just taken wonderful choice over others. This process can produce high precision net shape castings with no machining. Normally we can control such precision stainless steel casting with tolerance CT5-6 level. Another advantage is that, with this process, our foundry can supply stainless steel casting with no defects.

Gradus Materialium Communium Fusio Chalybis Inoxidabilis

SS304: Chalybs austeniticus latissime adhibitus, fortasse chalybs inoxidabilis A2 appellari potest.

SS316: Secunda chalybs austenita vulgatissima, etiam chalybs inoxidabilis A4 appellata, SS316 imprimis propter auctam resistentiam corrosionis adhibetur.

Inoxidabilis 304L et Inoxidabilis 316L (superaustenitic stainless steel): The [L” means that the carbon content of the alloy is below 0.03%, which reduces the sensitization effect caused by the high temperatures involved in welding. Compare with 300 series, it shows better resistance to stress-corrosion cracking.

17-4 PH: Frequentissima chalybs inoxidabilis martensitica praecipitatione durissima, quae circiter 17% chromii et 4% niccoli utitur.

Tractationes Superficiales Fusorum Chalybis Inoxidabilis

Iaculatio IaculatoriaAdhibetur ad removendam superficiem nigri oxidi post fusuram productorum chalybis inoxidabilis.

Decaptatio et Passivatio: Pickling is a chemical treatment way to eliminate surface dirts like oxide skin, rust, welding spots,ect. And passivation is a process that forming a new abundant chromium protective layer, thus to improve the anti-oxidation ability of stainless steel castings.

ElectropolituraAdhibetur ad minimas bavas superficiales removendas et splendorem fusorum chalybis inoxidabilis augendum.

Politura SpeculiGenus poliendi superficiem qua superficiem lenem et nitentem, instar speculi, consequi potest.

Applicatio Fusurarum Chalybis Inoxidabilis

For the unique physical properties of stainless steel, Stainless steel castings are served for a wide range of industries, especially those in severe environments. Below are the main applications of stainless steel casting

officina nostra