Industrial Casting

-

Custom cast iron ring

Cast iron is an alloy consisting mainly of iron, carbon, and silicon.

In these alloys, the carbon content exceeds the amount that can be retained in austenite solid solution at eutectic temperature.

Cast iron is an iron-carbon alloy with a carbon content greater than 2.11% (generally 2.5 ~ 4%).It is a multi-element alloy with iron, carbon and silicon as the main component elements and contains more manganese, sulfur, phosphorus and other impurities than carbon steel.Sometimes in order to improve the mechanical properties of cast iron or physical, chemical properties, but also add a certain amount of alloy elements, alloy cast iron.

As early as the sixth century BC age period, China has begun to use cast iron, than European countries nearly two thousand years earlier.Cast iron is still one of the most important materials in industrial production.

oneAccording to the form of carbon present in cast iron, cast iron can be divided into

1.White cast iron except for a few soluble in ferrite, the rest of the carbon in the form of cementite exists in cast iron, its fracture is silver-white, so called white cast iron.White cast iron is mainly used as raw material for steelmaking and blank for producing malleable cast iron.

2.Gray cast iron carbon all or most of the flake graphite exists in the cast iron, its fracture is dark gray, so called gray cast iron.

3.Part of the carbon of hemp cast iron exists in the form of graphite, which is similar to gray cast iron.The other part is in the form of free cementite similar to white cast iron.The black and white pitting in the fracture, so called hemp cast iron.This type of cast iron also has greater hardness and brittleness, so it is rarely used in the industry.

twoAccording to the different graphite morphology in cast iron, cast iron can be divided into

1.The graphite in gray cast iron is flake.

2.The graphite in malleable cast iron is flocculent.It is obtained from certain white cast iron after annealing at high temperature for a long time.Its mechanical properties (especially toughness and plasticity) are higher than gray cast iron, so it is commonly called malleable cast iron.

3.The graphite in nodular cast iron is spherical.It is obtained by spheroidizing treatment before pouring molten iron.This kind of cast iron not only has higher mechanical properties than gray cast iron and malleable cast iron, but also has a simpler production process than malleable cast iron. Moreover, its mechanical properties can be further improved through heat treatment, so it is increasingly widely used in production.

-

Custom cast iron case

Cast iron is an alloy consisting mainly of iron, carbon, and silicon.

In these alloys, the carbon content exceeds the amount that can be retained in austenite solid solution at eutectic temperature.

Cast iron is an iron-carbon alloy with a carbon content greater than 2.11% (generally 2.5 ~ 4%).It is a multi-element alloy with iron, carbon and silicon as the main component elements and contains more manganese, sulfur, phosphorus and other impurities than carbon steel.Sometimes in order to improve the mechanical properties of cast iron or physical, chemical properties, but also add a certain amount of alloy elements, alloy cast iron.

As early as the sixth century BC age period, China has begun to use cast iron, than European countries nearly two thousand years earlier.Cast iron is still one of the most important materials in industrial production.

oneAccording to the form of carbon present in cast iron, cast iron can be divided into

1.White cast iron except for a few soluble in ferrite, the rest of the carbon in the form of cementite exists in cast iron, its fracture is silver-white, so called white cast iron.White cast iron is mainly used as raw material for steelmaking and blank for producing malleable cast iron.

2.Gray cast iron carbon all or most of the flake graphite exists in the cast iron, its fracture is dark gray, so called gray cast iron.

3.Part of the carbon of hemp cast iron exists in the form of graphite, which is similar to gray cast iron.The other part is in the form of free cementite similar to white cast iron.The black and white pitting in the fracture, so called hemp cast iron.This type of cast iron also has greater hardness and brittleness, so it is rarely used in the industry.

twoAccording to the different graphite morphology in cast iron, cast iron can be divided into

1.The graphite in gray cast iron is flake.

2.The graphite in malleable cast iron is flocculent.It is obtained from certain white cast iron after annealing at high temperature for a long time.Its mechanical properties (especially toughness and plasticity) are higher than gray cast iron, so it is commonly called malleable cast iron.

3.The graphite in nodular cast iron is spherical.It is obtained by spheroidizing treatment before pouring molten iron.This kind of cast iron not only has higher mechanical properties than gray cast iron and malleable cast iron, but also has a simpler production process than malleable cast iron. Moreover, its mechanical properties can be further improved through heat treatment, so it is increasingly widely used in production.

-

Cast iron valve coupling

Cast iron is an alloy consisting mainly of iron, carbon, and silicon.

In these alloys, the carbon content exceeds the amount that can be retained in austenite solid solution at eutectic temperature.

Cast iron is an iron-carbon alloy with a carbon content greater than 2.11% (generally 2.5 ~ 4%).It is a multi-element alloy with iron, carbon and silicon as the main component elements and contains more manganese, sulfur, phosphorus and other impurities than carbon steel.Sometimes in order to improve the mechanical properties of cast iron or physical, chemical properties, but also add a certain amount of alloy elements, alloy cast iron.

As early as the sixth century BC age period, China has begun to use cast iron, than European countries nearly two thousand years earlier.Cast iron is still one of the most important materials in industrial production.

oneAccording to the form of carbon present in cast iron, cast iron can be divided into

1.White cast iron except for a few soluble in ferrite, the rest of the carbon in the form of cementite exists in cast iron, its fracture is silver-white, so called white cast iron.White cast iron is mainly used as raw material for steelmaking and blank for producing malleable cast iron.

2.Gray cast iron carbon all or most of the flake graphite exists in the cast iron, its fracture is dark gray, so called gray cast iron.

3.Part of the carbon of hemp cast iron exists in the form of graphite, which is similar to gray cast iron.The other part is in the form of free cementite similar to white cast iron.The black and white pitting in the fracture, so called hemp cast iron.This type of cast iron also has greater hardness and brittleness, so it is rarely used in the industry.

twoAccording to the different graphite morphology in cast iron, cast iron can be divided into

1.The graphite in gray cast iron is flake.

2.The graphite in malleable cast iron is flocculent.It is obtained from certain white cast iron after annealing at high temperature for a long time.Its mechanical properties (especially toughness and plasticity) are higher than gray cast iron, so it is commonly called malleable cast iron.

3.The graphite in nodular cast iron is spherical.It is obtained by spheroidizing treatment before pouring molten iron.This kind of cast iron not only has higher mechanical properties than gray cast iron and malleable cast iron, but also has a simpler production process than malleable cast iron. Moreover, its mechanical properties can be further improved through heat treatment, so it is increasingly widely used in production.

-

Cast iron valve fittings

Cast iron is an alloy consisting mainly of iron, carbon, and silicon.

In these alloys, the carbon content exceeds the amount that can be retained in austenite solid solution at eutectic temperature.

Cast iron is an iron-carbon alloy with a carbon content greater than 2.11% (generally 2.5 ~ 4%).It is a multi-element alloy with iron, carbon and silicon as the main component elements and contains more manganese, sulfur, phosphorus and other impurities than carbon steel.Sometimes in order to improve the mechanical properties of cast iron or physical, chemical properties, but also add a certain amount of alloy elements, alloy cast iron.

As early as the sixth century BC age period, China has begun to use cast iron, than European countries nearly two thousand years earlier.Cast iron is still one of the most important materials in industrial production.

oneAccording to the form of carbon present in cast iron, cast iron can be divided into

1.White cast iron except for a few soluble in ferrite, the rest of the carbon in the form of cementite exists in cast iron, its fracture is silver-white, so called white cast iron.White cast iron is mainly used as raw material for steelmaking and blank for producing malleable cast iron.

2.Gray cast iron carbon all or most of the flake graphite exists in the cast iron, its fracture is dark gray, so called gray cast iron.

3.Part of the carbon of hemp cast iron exists in the form of graphite, which is similar to gray cast iron.The other part is in the form of free cementite similar to white cast iron.The black and white pitting in the fracture, so called hemp cast iron.This type of cast iron also has greater hardness and brittleness, so it is rarely used in the industry.

twoAccording to the different graphite morphology in cast iron, cast iron can be divided into

1.The graphite in gray cast iron is flake.

2.The graphite in malleable cast iron is flocculent.It is obtained from certain white cast iron after annealing at high temperature for a long time.Its mechanical properties (especially toughness and plasticity) are higher than gray cast iron, so it is commonly called malleable cast iron.

3.The graphite in nodular cast iron is spherical.It is obtained by spheroidizing treatment before pouring molten iron.This kind of cast iron not only has higher mechanical properties than gray cast iron and malleable cast iron, but also has a simpler production process than malleable cast iron. Moreover, its mechanical properties can be further improved through heat treatment, so it is increasingly widely used in production.

-

Manhole covers

product presentation :

Good toughness.The impact value is similar to that of medium carbon steel, which is more than 10 times of gray iron material.

Strong corrosion resistance.In the water spray corrosion test, the corrosion amount in 90 days is only 1/40 of that of steel pipe and 1/10 of that of gray iron pipe.The service life is 2 times of gray iron pipe and 5 times of ordinary steel pipe.

Good plasticity.Elongation ≥7%, similar to high carbon steel, but gray iron material elongation is zero.

High strength.The tensile strength ob ≥420MPa and yield strength OS ≥300MPa are the same as low carbon steel and three times as gray iron material.

Because of its nodular graphite microstructure, ductile iron is better than cast steel in reducing vibration capacity, so it is more beneficial to reduce stress.An important reason for choosing ductile iron is that ductile iron costs less than cast steel.The low cost of ductile iron makes this material more popular, more efficient, and less costly to machine.

The strength of ductile iron is comparable to that of cast steel.Ductile iron has a higher yield strength, with a minimum yield strength of 40K and cast steel yield strength of only 36K.Ductile iron is more resistant to corrosion and oxidation than cast steel in most municipal applications such as water, salt water, steam, etc.

-

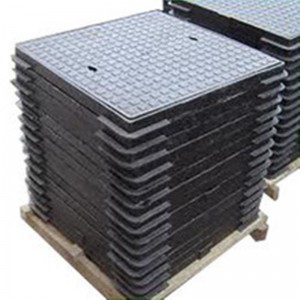

Cast iron manhole covers

product presentation :

Good toughness.The impact value is similar to that of medium carbon steel, which is more than 10 times of gray iron material.

Strong corrosion resistance.In the water spray corrosion test, the corrosion amount in 90 days is only 1/40 of that of steel pipe and 1/10 of that of gray iron pipe.The service life is 2 times of gray iron pipe and 5 times of ordinary steel pipe.

Good plasticity.Elongation ≥7%, similar to high carbon steel, but gray iron material elongation is zero.

High strength.The tensile strength ob ≥420MPa and yield strength OS ≥300MPa are the same as low carbon steel and three times as gray iron material.

Because of its nodular graphite microstructure, ductile iron is better than cast steel in reducing vibration capacity, so it is more beneficial to reduce stress.An important reason for choosing ductile iron is that ductile iron costs less than cast steel.The low cost of ductile iron makes this material more popular, more efficient, and less costly to machine.

The strength of ductile iron is comparable to that of cast steel.Ductile iron has a higher yield strength, with a minimum yield strength of 40K and cast steel yield strength of only 36K.Ductile iron is more resistant to corrosion and oxidation than cast steel in most municipal applications such as water, salt water, steam, etc.

-

Custom grates

product presentation:

Grizzley grates are a group of cast-iron grates used to cover grates, pits, and other protective grates that protect a person's safety or protect trees and other protective elements from damage.

The gratings are rain gratings, tree gratings, grate gratings, floor gratings, etc.For example, iron grates are often placed on the drains of bathhouses, allowing water to flow in and preventing foot and foot injuries.

-

Resin covers

product presentation :

1. Strong anti-theft performance: resin composite material manhole cover using unsaturated resin, glass fiber and other material and reinforced skeleton compounded by the special production process, after high temperature and press for a forming, material recycling value, it is very difficult to remove the steel bar (take out the value of steel costs more than steel) so it is of active anti-theft function.

2. Large bearing capacity: the bottom of the special pot bottom structure, so that the stressed area increased ten times or even dozens of times.The continuous reinforcement fiber is used to ensure the fiber fiber and glass fiber cloth are integrated in the material, so that the product has sufficient carrying capacity.And meet or exceed national standards.

3. Long service life, through the adoption of high performance resin, glass fiber and special formula, production process to ensure that the penetration of resins in glass fiber, greatly enhanced the stick relay, make the material under cyclic loading, do not produce internal damage, so as to ensure the service life of the product, and other resin composite manhole cover with the same advantages.Put an end to the drawbacks of poor adhesion.

4. Beautiful and practical, high grade: According to the needs of high-end customers, we can make a complex LOGO and a variety of colors on the same manhole cover surface of personalized design, so that the pattern is delicate, bright colors, distinct.And can be made according to customer demand and all kinds of stone pavement the same imitation stone surface and color.

5. High/low temperature resistance, good insulation and strong corrosion resistance: corrosion resistance, non-toxic and harmless.No metal additives, played a real sense of insulation effect.It can be used in complex, changeable, harsh and demanding places.The products have been tested by the relevant national authoritative testing institutions, with obvious acid and alkali resistance, corrosion resistance, anti-aging and other indicators have reached and exceeded the national standards.

6. Environmental protection, anti-skid, low noise: the product will not slip, no harsh noise and reverse phenomenon after the vehicle is run over.At the same time, due to the light weight of the product, cover, seat buckle precision, overcome other inspection cover "jump, stilt, sound, displacement" and other problems.

-

Stainless Steel pipe fittings

OEM Stainless Steelcastings, lost wax production craft, machining choice will be according to the actual tolerance request and demand quantity. Most of Our produced castings are used for valves, hydrants, pumps,trucks,railway and train and so on.

Manufacturing technique:Lost Wax Precision Casting

Material: SS316, SS304, 1.4310

Product weight:0.2Kg-200Kg