High Pressure Aluminum Die Casting Parts

Product Description

Aluminium is the most abundant metal of all, as it makes up 8% of the Earth`s crust, and its non-magnetic and ductile properties allow it to have a wide range of applications. One of these applications is within alloys, with the most popular combinations including materials such as copper, zinc and magnesium. Aluminium alloys are created via the die casting process in order to improve the properties of the metal, mainly to increase its strength, since pure aluminium is relatively soft.

Aluminium alloys are used in many different industries, sectors and products, such as aerospace, automotive, military, transportation, packaging, food preparation and electrical components. Each aluminium alloy has its own specific properties, so it is vital that you choose the one that best suits your needs and your project`s requirements. Still, the different alloys have some aspects in common:

- Lightness

- Resistance to corrosion

- High levels of strength

- Electrical and thermal conductivity

- Suitable for surface treatments

- Recyclable

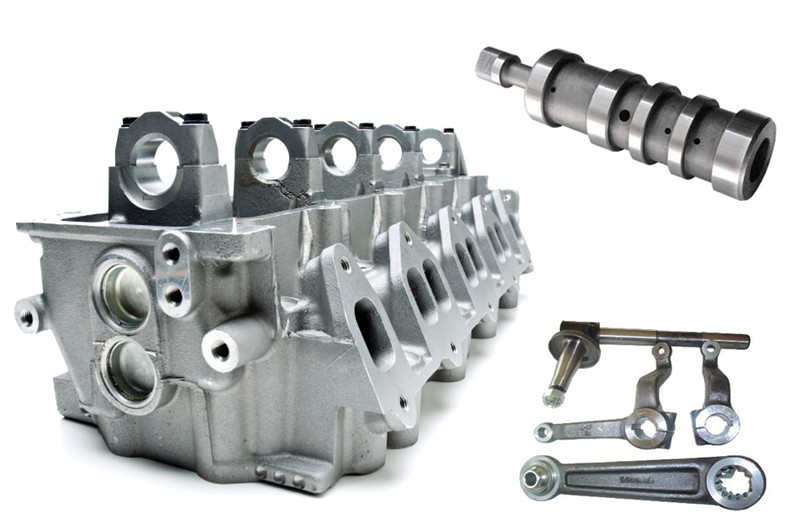

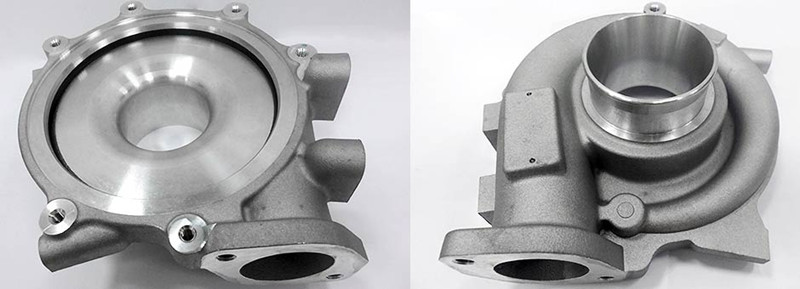

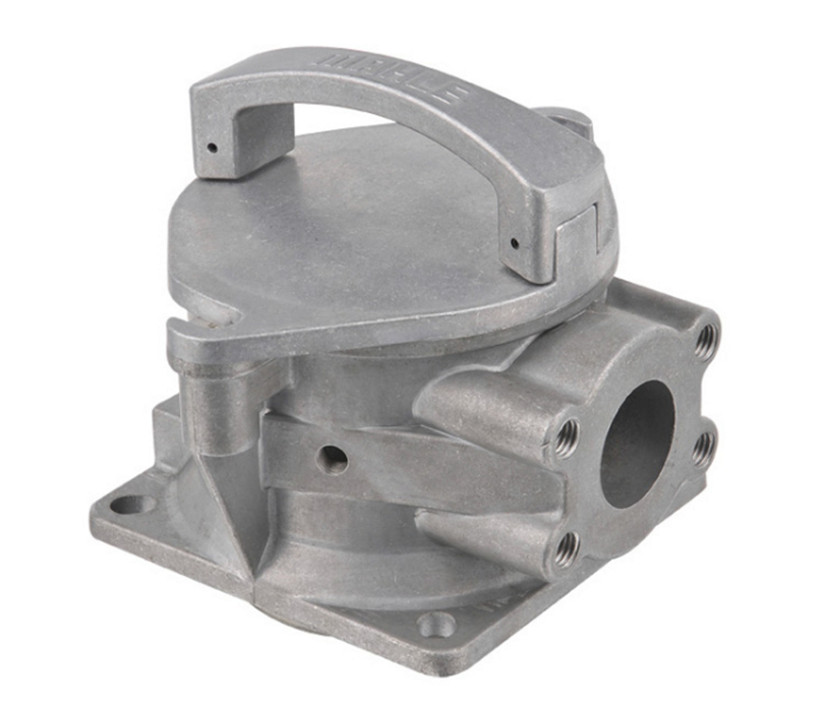

Products show