Wholesale Price Steel Mould; - OEM Custom Precision Casting Brass Bushing – Mingda

Wholesale Price Steel Mould; - OEM Custom Precision Casting Brass Bushing – Mingda Detail:

Basic Info

Casting Method: Thermal Gravity Casting

Process: Die Casting

Molding Technics: Pressure Casting

Application: Machinery Parts

Material: Metal

Surface Preparation: Polishing

Surface Roughness: Ra6.3

Machining Tolerance: +/-0.01mm

Standard: AISI

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

Hebei Mingda can produce precision castings using copper and a variety of copper-based alloy materials. Perhaps the most common are brass castings. Brass alloys, also known as [red-brass” or [yellow-brass” alloys, are mostly used in plumbing and door hardware due to their finishing and polishing qualities. Additionally, because U.S. environmental regulations have limited the allowable lead content in brass plumbing fixtures to minimize the leaching of lead particles into drinking water, the copper industry has developed a line of alloys that have all but eliminated lead, making them standard materials in the drinking water industry.

Bronze, most often used in bearings and similar components, is also a copper-based alloy, and is a very adaptable material that offers a broad range of properties from a wide selection of alloys and compositions. All bronzes have similar compositions and properties, but it is the added elements (tin, lead, aluminum, manganese) which provide the desired performance for the environment in which the alloy is used. Tin, for example, provides added strength. Lead increases bronze`s lubricity, but results in a decrease in strength. Increased aluminum and manganese content creates an ideal bronze alloy for applications that require both corrosion resistance and high strength.

Products show

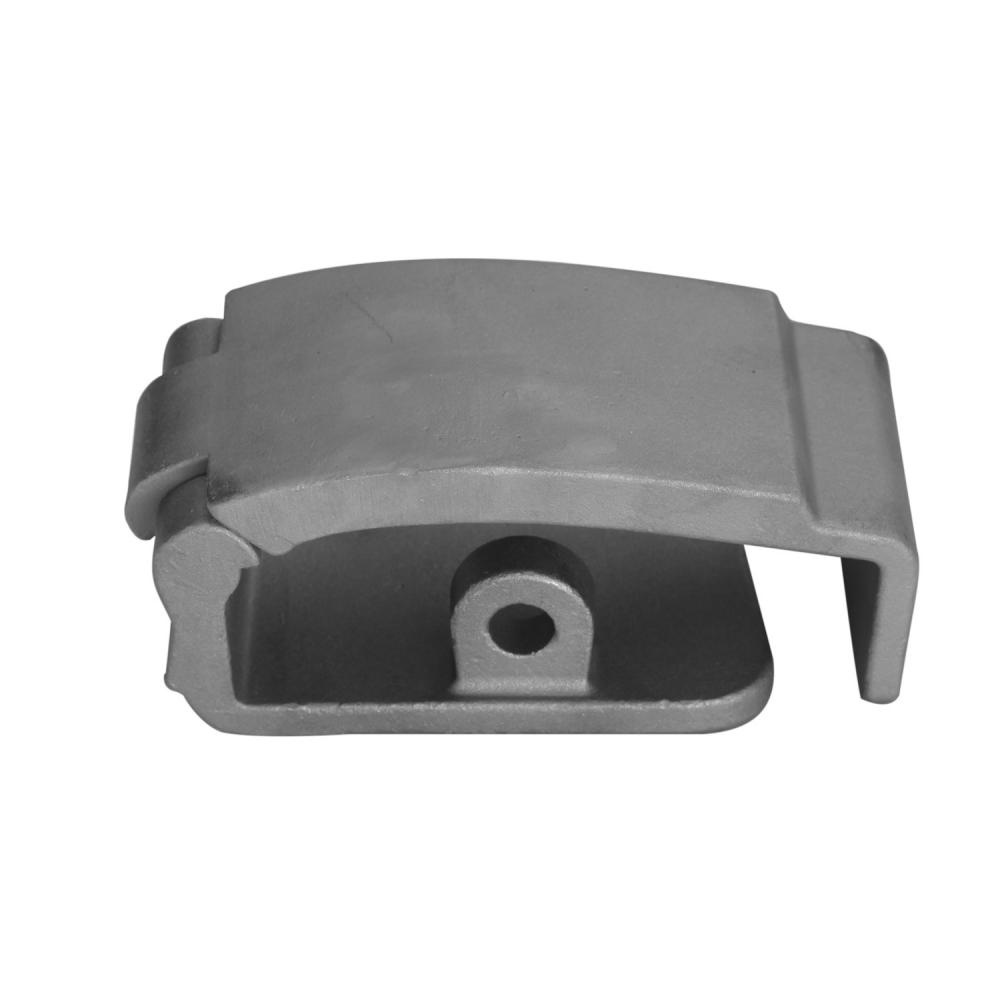

Product detail pictures:

Related Product Guide:

Our aim is usually to give superior quality items at aggressive rates, and top-notch company to clients around the earth. We have been ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for Wholesale Price Steel Mould; - OEM Custom Precision Casting Brass Bushing – Mingda , The product will supply to all over the world, such as: Pakistan, Sao Paulo, Guyana, Our tenet is integrity first, quality best. We have confidence in providing you with excellent service and ideal products. We sincerely hope we can establish win-win business cooperation with you in the future!

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.