Professional China Precision Machined Components - OEM Custom CNC Milling Service – Mingda

Professional China Precision Machined Components - OEM Custom CNC Milling Service – Mingda Detail:

Basic Info

Application: Auto and Motorcycle Accessory

Standard: ASME

Surface Treatment: Polishing

Production Type: Mass Production

Machining Method: CNC Milling

Material: Steel

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 10 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

CNC milling is the process of rotating a cutting tool in a spindled axis to produce a shape or form. The cutting tool is controlled by a specialized computer, which greatly increases reliability and repeatability, while reducing the potential for human error. Most milling machines are equipped with tool changers, which allow the machine to automatically switch between a variety of cutting tools.

Because of this, CNC milling is often referred to interchangeably as CNC machining, because both encompass a variety of operations that can be done within a CNC machining center. CNC milling also encompasses drilling, reaming, threading, tapping, and other operations, as they can be completed in the same setup.

With various tooling and ingenuity, CNC milling is capable of producing almost any shape. The wide range of potential milling applications also makes CNC machining the most variable service offers. Tolerance, surface finish, part size, tooling, and material properties can all directly affect pricing.

Whether a part is suited for 3-, 4-, or 5-axis milling depends greatly upon the dimensions and features of the part itself. In general, fewer setups are needed for milling machines with more axis. Completing as much geometry as possible in a single setup ensures greater feature-to-feature accuracy, as the machine`s zero remains the same.

Multiple-axis machinery requires complex, skillful, and meticulous programming. Providing a 3D CAD file can generally reduce time spent quoting or programming CNC milling code.

CNC MILLING CAPABILITIES

+/- 0.0005″ TOLERANCE

STAMPING DIES & MOLDS

ALL METALS/ALLOYS/PLASTICS

3-, 4-, & 5-AXIS MACHINING

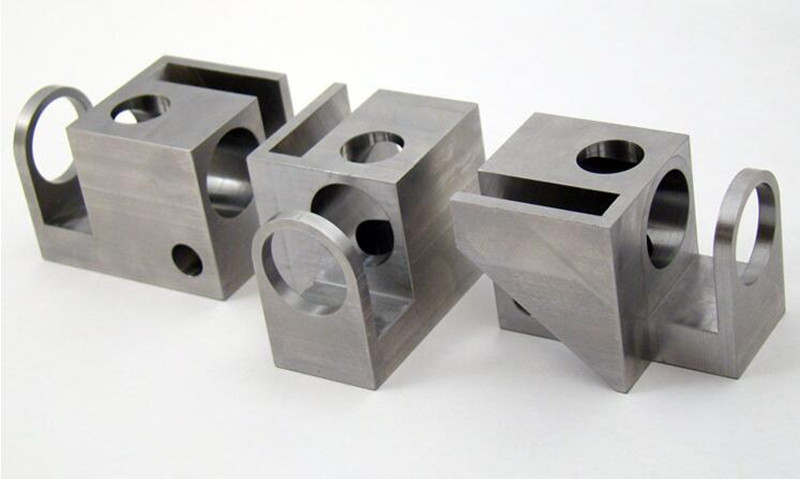

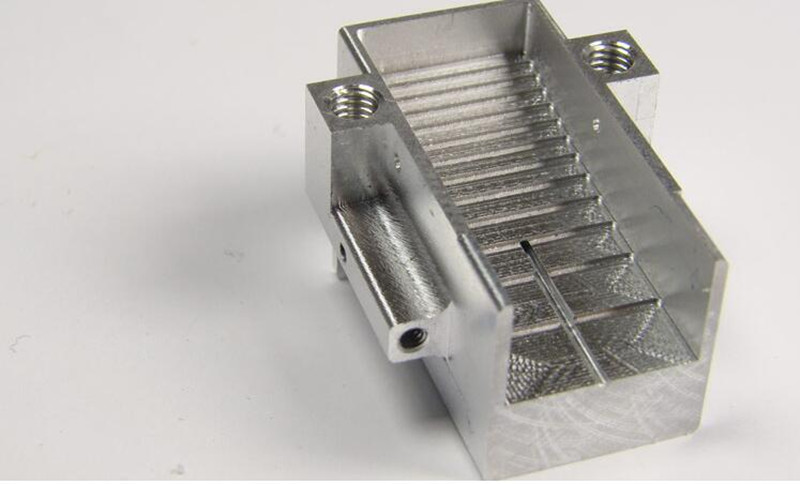

Product detail pictures:

Related Product Guide:

Our personnel are always inside the spirit of continuous improvement and excellence, and together with the outstanding excellent goods, favorable price and good after-sales services, we try to gain every customer's trust for Professional China Precision Machined Components - OEM Custom CNC Milling Service – Mingda , The product will supply to all over the world, such as: Estonia, Haiti, Sheffield, Now we have a excellent team supplying specialist service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We have been sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy with you. We also warmly welcome customers to visit our company and purchase our solutions.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.