PriceList for Lathe Bed - Aluminum Die Casting Vehicle Crankcase Housing – Mingda

PriceList for Lathe Bed - Aluminum Die Casting Vehicle Crankcase Housing – Mingda Detail:

Basic Info

Die Casting Machine Type: Cold Chamber Die Casting Machine

Die Casting Method: Precision Die Casting

Application: Machinery Parts

Machining: CNC Machining

Material: Aluminum

Surface Preparation: Polishing

Pressure Chamber Structure: Vertical

Tolerance Grade: 8

Casting Surface Quality Level: 3

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

Die casting is a manufacturing process that can produce geometrically complex metal parts through the use of reusable molds, called dies.

The die casting process involves the use of a furnace, metal, die casting machine, and die. The metal, typically a non-ferrous alloy such as aluminum or zinc, is melted in the

furnace and then injected into the dies in the die casting machine. There are two main types of die casting machines – hot chamber machines (used for alloys with low melting

temperatures, such as zinc) and cold chamber machines (used for alloys with high melting temperatures, such as aluminum).

The differences between these machines will be detailed in the sections on equipment and tooling. However, in both machines, after the molten metal is injected into the dies,

it rapidly cools and solidifies into the final part, called the casting. The steps in this process are described in greater detail in the next section.

The castings that are created in this process can vary greatly in size and weight, ranging from a couple ounces to 100 pounds.

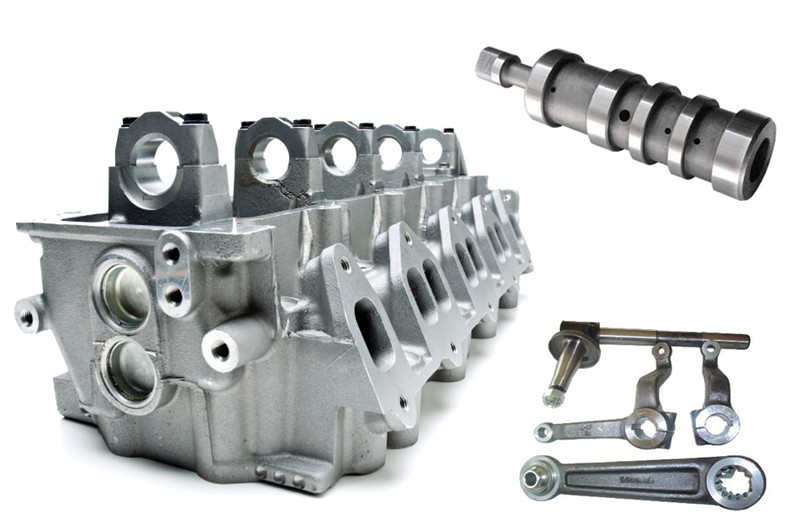

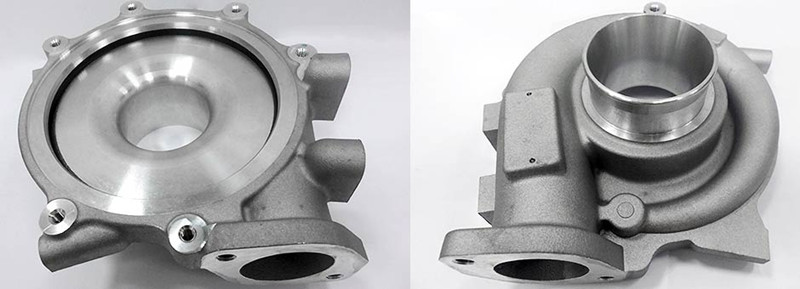

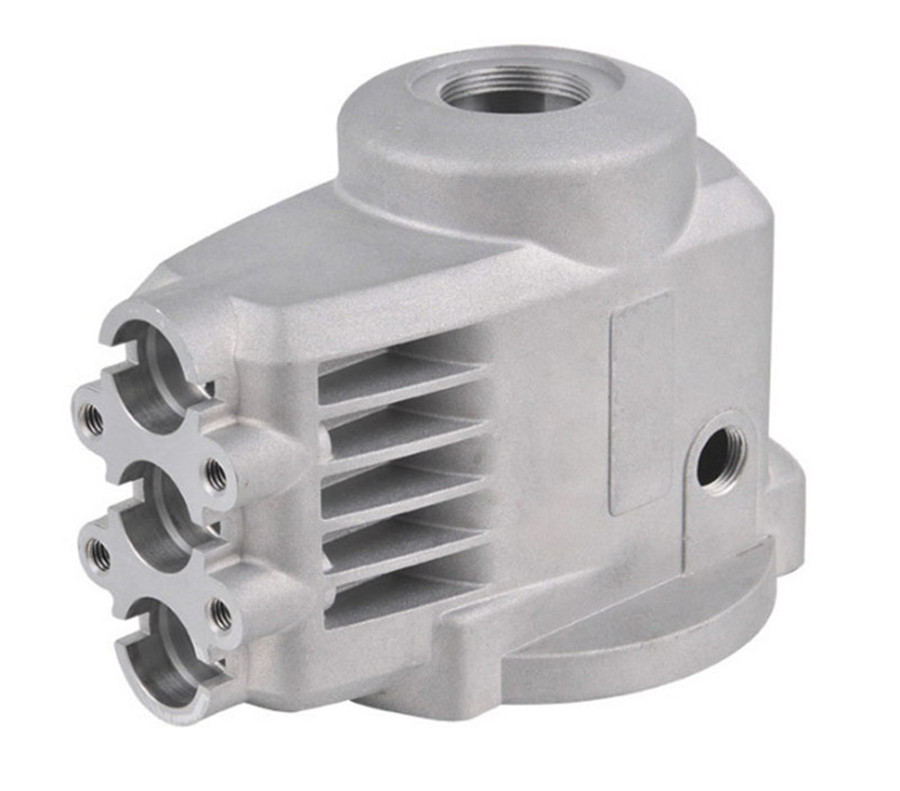

One common application of die cast parts are housings – thin-walled enclosures, often requiring many ribs and bosses on the interior. Metal housings for a variety of

appliances and equipment are often die cast. Several automobile components are also manufactured using die casting, including pistons, cylinder heads, and engine blocks.

Other common die cast parts include propellers, gears, bushings, pumps, and valves.

Products show

Product detail pictures:

Related Product Guide:

Which has a positive and progressive attitude to customer's desire, our corporation constantly improves our merchandise quality to satisfy the desires of consumers and further focuses on safety, reliability, environmental demands, and innovation of PriceList for Lathe Bed - Aluminum Die Casting Vehicle Crankcase Housing – Mingda , The product will supply to all over the world, such as: USA, Albania, Ireland, Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We are able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and products. For anyone who is interested in our company and items, please make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are going to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please really feel no cost to speak to us for enterprise. nd we believe we are going to share the most effective trading practical experience with all our merchants.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.