OEM manufacturer Aluminium Die Casting - High Pressure Aluminum Die Casting – Mingda

OEM manufacturer Aluminium Die Casting - High Pressure Aluminum Die Casting – Mingda Detail:

Basic Info

Die Casting Machine Type: Cold Chamber Die Casting Machine

Die Casting Method: Precision Die Casting

Application: Machinery Parts

Machining: CNC Machining

Material: Aluminum

Surface Preparation: Polishing

Pressure Chamber Structure: Vertical

Tolerance Grade: 8

Casting Surface Quality Level: 3

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

The aluminum die casting process refers to our high pressure die casting process that used for thin wall thickness parts. High pressure aluminum die casting is a process in which molten aluminum alloy is injected into casting molds under high pressure at a controlled temperature. After casting, the aluminum die casting blank will be stamped to remove flash around the edge of product. The whole aluminum die casting production process is fast and inexpensive than other casting methods. Below is the video which shows how our high pressure aluminum die casting process is made in our company.

What Is Aluminum Die Casting?

Aluminum die casting is a manufacturing process for producing accurately dimension, sharply defined, smooth or textured-surface aluminum parts through the use of reusable molds, called dies. The aluminum die casting process involves the use of a furnace, aluminum alloy, die casting machine, and die. Dies that usually constructed with long-lasting, quality steel have at least two sections to permit removal of castings.

Advantages of Aluminum Die Casting

- Simple or complex shapes

- Thin wall thickness

- Light weight

- High rates of production

- Corrosion resistance

- Monolithic – combine multiple functions in one

- Efficient and economical alternative to other processes

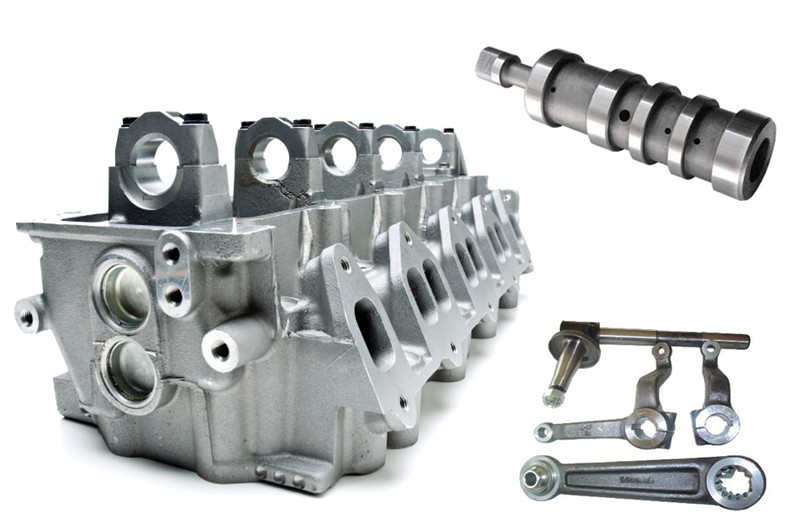

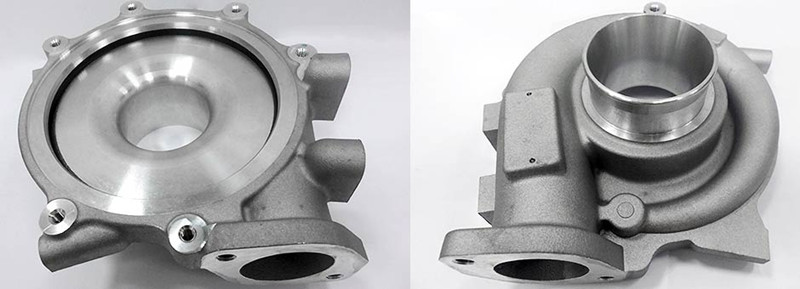

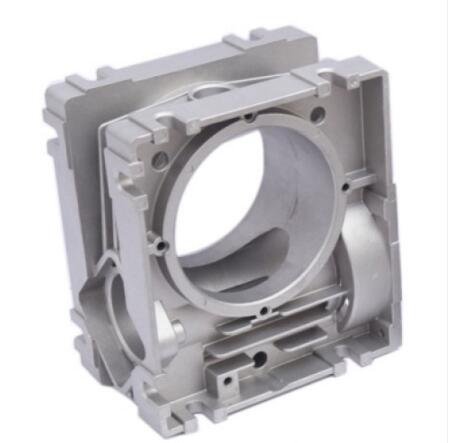

Products show

Product detail pictures:

Related Product Guide:

We always work as a tangible team to ensure that we can provide you with the best quality and the best price for OEM manufacturer Aluminium Die Casting - High Pressure Aluminum Die Casting – Mingda , The product will supply to all over the world, such as: Bahrain, Grenada, Cologne, Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!