OEM Factory for Cast Iron Flywheel - Aluminum Die Casting Shell Housing – Mingda

OEM Factory for Cast Iron Flywheel - Aluminum Die Casting Shell Housing – Mingda Detail:

Basic Info

Die Casting Machine Type: Cold Chamber Die Casting Machine

Die Casting Method: Precision Die Casting

Application: Machinery Parts

Machining: CNC Machining

Material: Aluminum

Surface Preparation: Polishing

Pressure Chamber Structure: Vertical

Tolerance Grade: 8

Casting Surface Quality Level: 3

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

Hebei Mingda provides superior quality aluminum die casting parts and components for a wide range of industries including automotive, food dairy, machinery, medical, plumbing, watering, mining, petrochemical, electrical, energy, aerospace, submarine and others.

Aluminum die casting is a great choice for manufacturing parts with the highly valued combination of light weight and superior strength at a high rate. With die casting machines ranging from 180 up to 2,000 metric tons and CNC machine centers, we can produce aluminum die casting parts from a few grams to more than 40 pounds with superior quality ready for assembly. For aluminum die casting parts with requirements of esthetical, functional, or protective coatings, we also offer a broad range of surface finishing including powder coating, e-coating, shot blasting, chrome plating, and bright finish.

What Is Aluminum Die Casting?

Aluminum die casting is a manufacturing process for producing accurately dimension, sharply defined, smooth or textured-surface aluminum parts through the use of reusable molds, called dies. The aluminum die casting process involves the use of a furnace, aluminum alloy, die casting machine, and die. Dies that usually constructed with long-lasting, quality steel have at least two sections to permit removal of castings.

Advantages of Aluminum Die Casting

- Simple or complex shapes

- Thin wall thickness

- Light weight

- High rates of production

- Corrosion resistance

- Monolithic – combine multiple functions in one

- Efficient and economical alternative to other processes

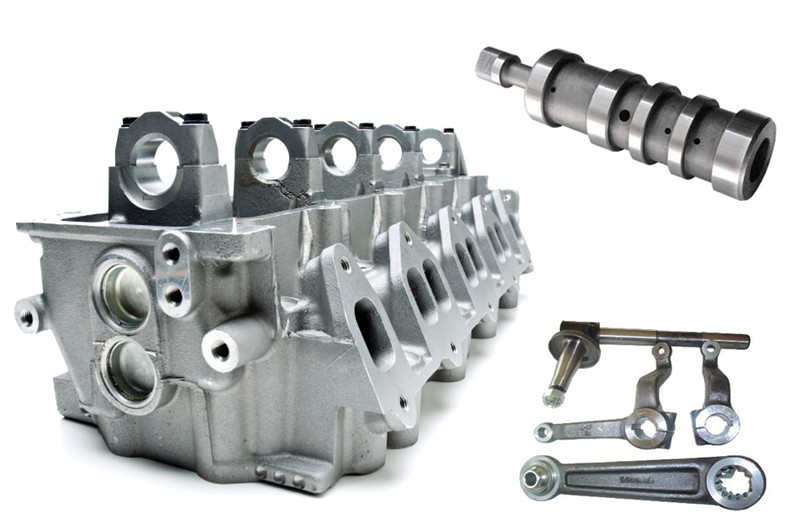

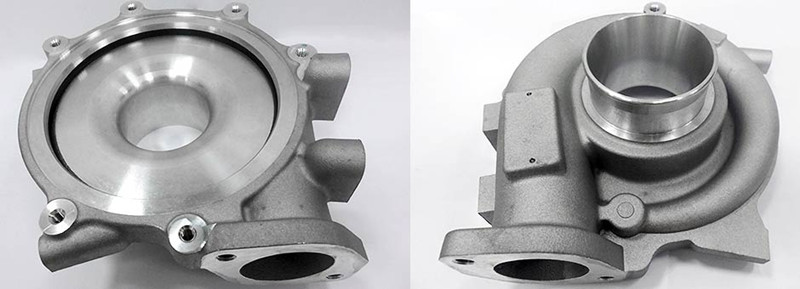

Products show

Product detail pictures:

Related Product Guide:

Our commission should be to provide our customers and consumers with ideal top quality and aggressive portable digital products for OEM Factory for Cast Iron Flywheel - Aluminum Die Casting Shell Housing – Mingda , The product will supply to all over the world, such as: Swedish, Armenia, London, By adhering to the principle of human oriented, winning by quality, our company sincerely welcomes merchants from at home and abroad to visit us, talk business with us and jointly create a brilliant future.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!