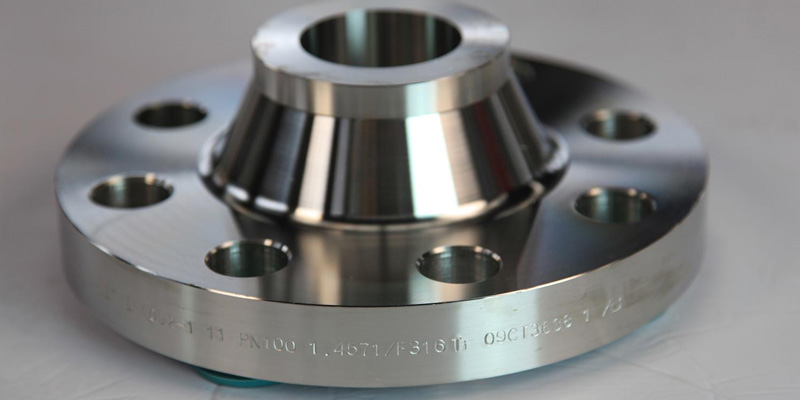

In critical industrial applications requiring robust, leak-proof connections, the a182 f316 stainless steel weld neck flange stands as a cornerstone component. Engineered for demanding environments, these flanges provide superior structural integrity and corrosion resistance, making them indispensable in various high-pressure and high-temperature systems. This comprehensive guide delves into the specifics of these vital components, from their advanced manufacturing processes to their extensive applications and technical advantages, providing B2B decision-makers and engineers with critical insights for optimal procurement and implementation.

The selection of materials like ASTM A182 Grade F316 stainless steel is predicated on its enhanced mechanical properties and excellent resistance to a broad spectrum of corrosive agents, especially chlorides and acids. This positions F316 weld neck flanges as a premier choice for industries where reliability and longevity are paramount. Understanding the intricacies of these components, including their adherence to ASME B16.5 standards, is crucial for ensuring system safety and operational efficiency.

The market for industrial flanges, particularly those made from specialized alloys, is experiencing steady growth driven by global infrastructure development, increasing energy demands, and stringent safety regulations. Key trends shaping the industry include:

The global industrial valves and fittings market, which includes flanges, is projected to grow significantly, with a CAGR often exceeding 4-5% over the next decade. This growth is primarily fueled by expansion in chemical processing, oil & gas, power generation, and water & wastewater treatment sectors, all of which are major consumers of the a182 f316 stainless steel weld neck flange.

The manufacturing of an ASME B16.5 a182 f316 stainless steel weld neck flange is a meticulous process that ensures adherence to stringent international standards for performance and reliability. It combines advanced metallurgical techniques with precision engineering:

High-quality A182 F316 stainless steel billets or bars are procured from certified suppliers. These raw materials undergo rigorous inspection, including Positive Material Identification (PMI) to confirm chemical composition (e.g., specific chromium, nickel, and molybdenum content that defines F316), and ultrasonic testing for internal defects.

The billets are heated to specific forging temperatures (typically 1100-1200°C) and then shaped into the approximate geometry of a weld neck flange using open-die or closed-die forging techniques. Forging refines the grain structure, enhances mechanical strength, and improves ductility, crucial for stress-bearing components. This process is superior to casting for critical applications due to the elimination of internal porosity.

Post-forging, the flanges undergo solution annealing. This involves heating the material to a high temperature (typically 1040-1150°C) followed by rapid quenching. This process dissolves carbide precipitates, homogenizes the microstructure, relieves internal stresses, and restores maximum corrosion resistance, particularly preventing intergranular corrosion.

The annealed forgings are then transferred to CNC (Computer Numerical Control) machining centers. Here, precise dimensions, including the bore, hub, facing (e.g., Raised Face, Flat Face), and bolt holes, are achieved. The critical weld neck profile is machined to ensure a perfect fit for butt welding, minimizing stress concentration at the joint. Surface finishes are also precisely controlled.

Bolt holes are accurately drilled and chamfered. Gasket contact surfaces are finished to specified roughness (e.g., serrated concentric or spiral finish) to ensure effective sealing.

Each flange undergoes extensive NDT, including liquid penetrant testing (PT) or magnetic particle testing (MT) for surface defects, and sometimes ultrasonic testing (UT) for internal integrity. Dimensional checks are performed against ASME B16.5 standards. Chemical analysis and mechanical property tests (tensile, impact, hardness) are conducted on test samples from the same heat number.

Some flanges may undergo passivation to enhance corrosion resistance by forming a protective oxide layer. Finally, each flange is marked with essential information: manufacturer's name/logo, material grade (F316), size, pressure class, heat number, and standard (ASME B16.5).

Flanges are protected with rust-preventative coatings or plastic end caps and carefully packaged to prevent damage during transit.

This rigorous process, often managed by a dedicated stainless steel weld neck flange factory, guarantees that each stainless steel weld neck flange meets the highest performance and safety requirements for a service life extending decades in demanding environments, showcasing significant advantages in energy saving through efficient sealing and unparalleled corrosion resistance.

The ASME B16.5 standard governs the dimensions, tolerances, marking, material, testing, and methods of designating openings for pipe flanges and flanged fittings. ASTM A182 specifies forged or rolled alloy and stainless steel pipe flanges, forged fittings, and valves and parts for high-temperature service. F316 is a popular austenitic stainless steel, known for its molybdenum content which significantly enhances corrosion resistance.

| Element | Min. (%) | Max. (%) |

|---|---|---|

| Carbon (C) | - | 0.08 |

| Manganese (Mn) | - | 2.00 |

| Phosphorus (P) | - | 0.045 |

| Sulfur (S) | - | 0.030 |

| Silicon (Si) | - | 1.00 |

| Chromium (Cr) | 16.00 | 18.00 |

| Nickel (Ni) | 10.00 | 14.00 |

| Molybdenum (Mo) | 2.00 | 3.00 |

| Property | Value | Unit |

|---|---|---|

| Tensile Strength (min.) | 515 | MPa |

| Yield Strength (0.2% Offset, min.) | 205 | MPa |

| Elongation (min.) | 30 | % |

| Hardness (Max.) | 217 | HBW |

The robust design and material properties of the a182 f316 stainless steel weld neck flange make it ideal for severe service conditions across numerous industries:

In these sectors, components like stainless steel weld on hubs and weld neck flanges are critical for maintaining system integrity and preventing costly leaks or failures, thereby reducing maintenance expenditures and ensuring continuous operation.

The selection of the a182 f316 stainless steel weld neck flange over other types of flanges (e.g., slip-on, socket-weld) and materials is often driven by a combination of inherent technical advantages:

Choosing the right supplier for stainless steel weld neck flange components is paramount for project success and long-term reliability. B2B purchasers should evaluate vendors based on several key criteria:

| Feature | High-Quality Supplier (e.g., Mingda Metals) | Standard Supplier |

|---|---|---|

| Certifications | ISO 9001, PED, ASME U-Stamp, API Q1, EN 10204 3.1/3.2 | Basic ISO 9001, limited material certificates |

| Forging Process | Advanced closed-die forging, optimized grain flow | Open-die or basic forging |

| Machining Precision | State-of-the-art 5-axis CNC, tight tolerances (±0.05mm) | Standard CNC, wider tolerances |

| Quality Control | In-house PMI, UT, MT/PT, Spectrograph analysis | Outsourced NDT, basic dimensional checks |

| Customization | Full bespoke design, engineering support, varied materials | Limited to standard modifications |

| Lead Time | Optimized production, reliable delivery schedules | Potentially longer or less consistent |

While ASME B16.5 outlines standard dimensions, many critical projects require tailored solutions. A reputable stainless steel weld neck flange factory can offer extensive customization for the a182 f316 stainless steel weld neck flange, including:

These customized solutions ensure that even the most complex engineering challenges can be met with precision-engineered components, guaranteeing optimal performance and system longevity.

An offshore oil and gas operator faced recurring issues with flange corrosion and leakage in sour gas (H2S-rich) transportation lines. Previous carbon steel and even 304L stainless steel flanges showed accelerated pitting corrosion, leading to costly shutdowns and environmental risks. After a detailed engineering review, they specified ASME B16.5 Class 900 6-inch a182 f316 stainless steel weld neck flange with RTJ facings. The high molybdenum content of F316 provided significantly improved resistance to hydrogen sulfide and chloride stress corrosion cracking. After three years of operation, the F316 flanges exhibited no signs of corrosion or leakage, contributing to increased operational uptime by 15% and a projected 20% reduction in maintenance costs over a five-year period.

A major chemical producer was upgrading an acid feed system handling dilute sulfuric acid and various organic chlorides. They required a robust piping connection solution that could withstand aggressive chemical attack and fluctuating temperatures up to 150°C. Standard flanges were prone to gasket failure and crevice corrosion. They opted for customized stainless steel weld neck flange made from A182 F316, engineered for a specific corrosive medium. The vendor provided comprehensive material certificates (EN 10204 3.2) and performed in-house simulated corrosion testing. The installation led to a 99.8% uptime for the system, exceeding previous performance by 10%, and eliminated unscheduled flange replacements, ensuring continuous production.

A large-scale seawater desalination plant utilized high-pressure reverse osmosis (RO) units. The piping connecting these units to the main headers experienced extreme pressures (up to 80 bar) and highly corrosive seawater conditions. Initial installations using lower-grade stainless steel showed signs of premature failure. By specifying custom-forged stainless steel weld on hubs and weld neck flanges from A182 F316, the plant achieved significantly enhanced reliability. The inherent resistance of F316 to chloride-induced corrosion proved vital, extending the mean time between failures (MTBF) for these critical connections by over 50%, resulting in substantial savings on repairs and increased fresh water output.

Standard size and pressure class stainless steel weld neck flange components typically have lead times ranging from 2-4 weeks, depending on inventory levels and order volume. For custom-fabricated or large-scale project orders, lead times can extend to 6-12 weeks. Our advanced production planning and logistics ensure timely delivery, with expedited options available for urgent requirements. We prioritize transparent communication regarding order status and estimated delivery dates.

All our ASME B16.5 a182 f316 stainless steel weld neck flange products come with a comprehensive warranty against manufacturing defects and material faults. The standard warranty period is 12-24 months from the date of delivery or 18 months from installation, whichever comes first. This commitment underscores our confidence in the quality and durability of our products, providing peace of mind to our clients.

We offer dedicated technical support from our team of experienced engineers, available for pre-sale consultations, specification guidance, and post-sale troubleshooting. Our global service network ensures prompt responses to inquiries and efficient resolution of any issues. Comprehensive documentation, including MTRs (Material Test Reports) and quality control certificates, is provided with every order to ensure full traceability and compliance.

The selection and implementation of the a182 f316 stainless steel weld neck flange are critical decisions for engineers and procurement specialists in demanding B2B sectors. Its superior material composition, robust forged construction, and adherence to international standards like ASME B16.5 ensure unparalleled performance in high-pressure, high-temperature, and corrosive environments. By understanding the detailed manufacturing process, leveraging technical advantages, and partnering with a reputable stainless steel weld neck flange factory capable of delivering customized solutions, industries can significantly enhance operational safety, extend equipment lifespan, and reduce total cost of ownership. Investing in quality F316 weld neck flanges is an investment in the long-term integrity and efficiency of critical piping systems.