Manufacturing Companies for Polymer Concrete Trench - Precision Lost Wax Investment Die Casting – Mingda

Manufacturing Companies for Polymer Concrete Trench - Precision Lost Wax Investment Die Casting – Mingda Detail:

Basic Info

Casting Method: Thermal Gravity Casting

Process: Lost Wax Casting

Molding Technics: Pressure Casting

Application: Machinery Parts

Material: Stainless Steel

Surface Preparation: Polishing

Surface Roughness: Ra6.3

Machining Tolerance: +/-0.01mm

Standard: AISI

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

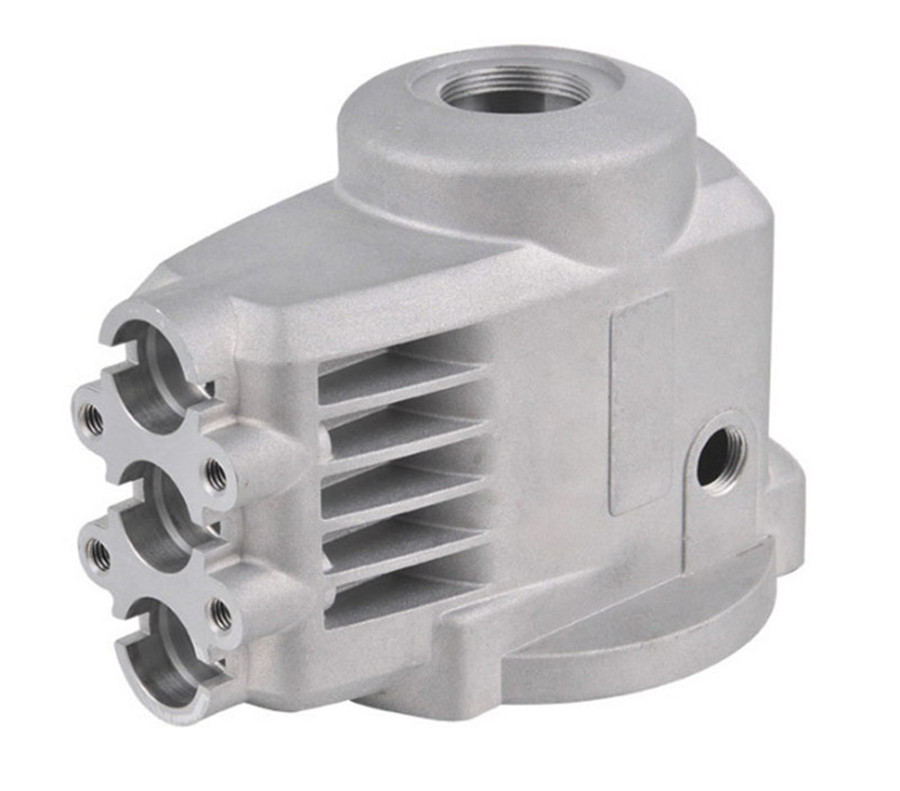

Investment Casting, also known as Lost Wax Casting, is a precision casting process that provides design flexibility and significant cost advantages.

The Investment Casting process involves pouring molten metal into a mold that has been created using a wax model. Once the mold is made, the wax model is melted and drained away.Hollow cores can be effected by using a heat-proof core that prevents the molten metal from totally filling the mold.

Investment Casting is generally used for small castings, but can be used to produce much larger components.

Dimensional tolerances of ± 0.003 in./in. are readily achieved. Delicate parts with walls as thin as 0.025 in. can be achieved by investment casting.

Common Material Grades of Stainless Steel Casting

SS304: The most widely used austenite steel, may be referred to as A2 stainless.

SS316: The second most common austenite steel, also referred to as A4 stainless. SS316 is used primarily for its increased resistance to corrosion.

SS304L & SS316L (superaustenitic stainless steel): The [L” means that the carbon content of the alloy is below 0.03%, which reduces the sensitization effect caused by the high temperatures involved in welding. Compare with 300 series, it shows better resistance to stress-corrosion cracking.

17-4 PH: Most common precipitation-hardening martensitic stainless steel, which uses about 17% chromium and 4% nickel.

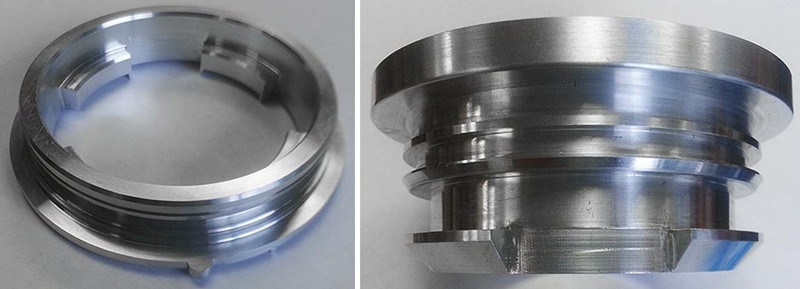

Surface Treatments of Stainless Steel Castings

Shot Blasting: Used to remove surface black oxide skin after casting of stainless steel products.

Pickling & Passivation Treatment: Pickling is a chemical treatment way to eliminate surface dirts like oxide skin, rust, welding spots,ect. And passivation is a process that forming a new abundant chromium protective layer, thus to improve the anti-oxidation ability of stainless steel castings.

Electropolishing: Used to remove surface tiny burrs and improve the brightness of stainless steel castings.

Mirror Polishing: A kind of surface polishing way that can achieve a smooth and shining surface like a mirror finish.

Application of Stainless Steel Castings

For the unique physical properties of stainless steel, Stainless steel castings are served for a wide range of industries, especially those in severe environments. Below are the main applications of stainless steel casting

our factory

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Quality is our life. Shopper need is our God for Manufacturing Companies for Polymer Concrete Trench - Precision Lost Wax Investment Die Casting – Mingda , The product will supply to all over the world, such as: Romania, Ottawa, New Orleans, Now, we are trying to enter new markets where we do not have a presence and developing the markets we have now the already penetrated. On account of superior quality and competitive price , we'll be the market leader, be sure to don??¥t hesitate to contact us by phone or email, if you are interested in any of our solutions.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!