Manufacturing Companies for Polymer Concrete Trench - Metal Processing Machinery Part in Investment Casting – Mingda

Manufacturing Companies for Polymer Concrete Trench - Metal Processing Machinery Part in Investment Casting – Mingda Detail:

Basic Info

Application: Auto and Motorcycle Accessory, Machinery Accessory

Standard: ASME

Surface Treatment: Polishing

Production Type: Mass Production

Machining Method: CNC Machining

Material: Steel

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

We can offer you investment casting parts, railway casting parts, railway parts, excavator machinery parts, mining machinery parts, engineering machinery, agricultural machinery parts, sand casting, auto parts, stamping & forging, and valve parts. We are capability in manufacture non-standard metal machining.

Investment casting sand casting/ lost wax casting/precision casting/gravity casting/stainless steel casting/carbon steel casting/ die casting/cookware handle casting/

pan handle casting/home hardware casting;

There are two types of investment cast processes: Silica Sol process and the water glass process.

The Silica Sol process is used to cast complex high quality parts with requirements of a very good surface finish and close dimensional tolerances.

This process can range from a weight of just a few ounces to approximately 80 pounds. If you are concerned with precision in very small parts, we are especially proficient at very fine detail work including teeth and serrations.

The water glass process is typical of the process in the early stages of investment castings. It generally is capable of much larger castings than the Silica Sol process, but does not have as good of surface finish or tolerances. The water glass process provides parts that have better surface finish and dimensional tolerances than sand castings.

This process may range in weight from several ounces to approximately 200 pounds.

First article layouts and spectrometer material certifications are provided with all first article samples.

Custom service: A variety of secondary operations can be performed on both types of investment castings. They include heat treatment, machining, plating, painting, polishing and buffing, assembly services and even custom packaging.

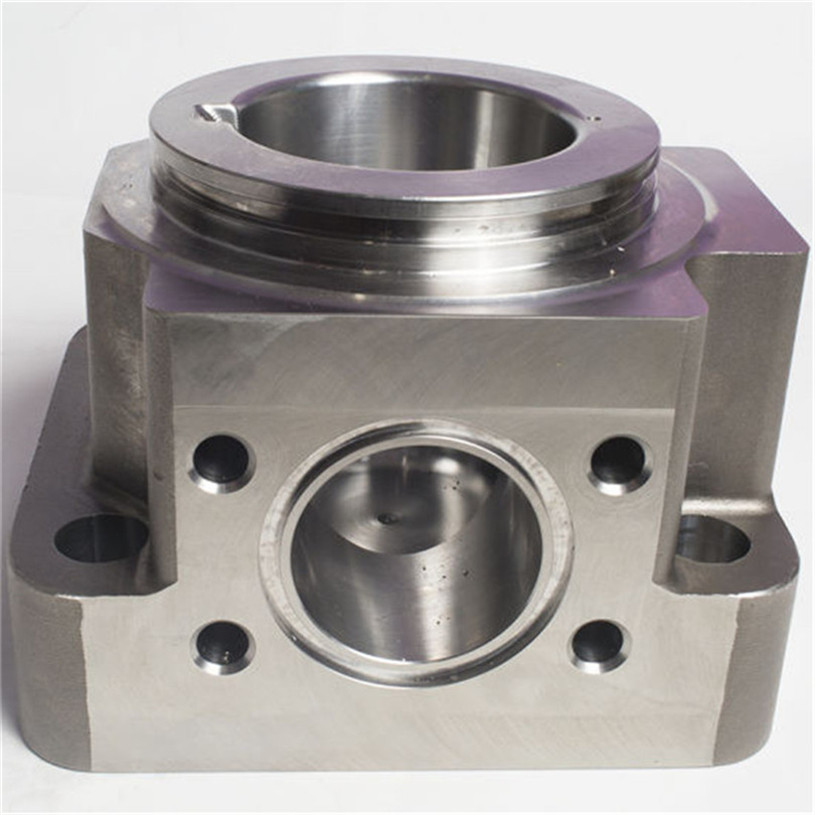

Products show

Product detail pictures:

Related Product Guide:

Bear Customer initially, High-quality first in mind, we work closely with our prospects and supply them with efficient and specialist companies for Manufacturing Companies for Polymer Concrete Trench - Metal Processing Machinery Part in Investment Casting – Mingda , The product will supply to all over the world, such as: United Arab Emirates, kazakhstan, Liverpool, The working experience in the field has helped us forged a strong relations with customers and partners both in domestic and international market. For years, our products have been exported to more than 15 countries in the world and have been widely used by customers.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!