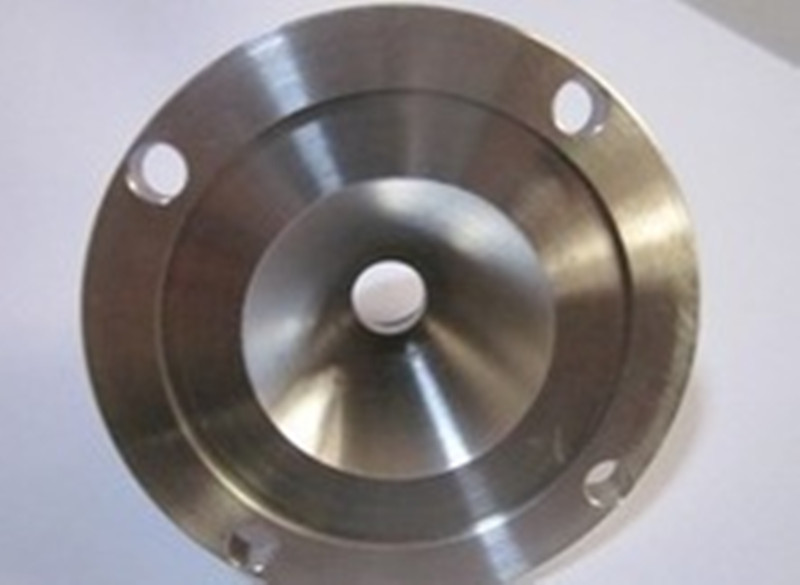

Hot-selling Resin Sand Moulding - OEM Stainless Steel Casting with Investment Casting – Mingda

Hot-selling Resin Sand Moulding - OEM Stainless Steel Casting with Investment Casting – Mingda Detail:

Basic Info

Casting Method: Thermal Gravity Casting

Process: Lost Wax Casting

Molding Technics: Pressure Casting

Application: Machinery Parts

Material: Stainless Steel

Surface Preparation: Polishing

Surface Roughness: Ra6.3

Machining Tolerance: +/-0.01mm

Standard: AISI

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 10 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

Process Overview

The investment casting process begins with a pattern. Traditionally, the pattern was injection mould in foundry wax. Gates and vents are attached to the pattern, which is then attached to the pure. After all patterns are mounted to the sprue producing what is called casting tree. At these points casting is ready for shelling. The casting tree is repeatedly dipped in ceramic slurry to create a hard shell that is called investment. The patterns are then melted out (also called burnout) of the investment, leaving a cavity in the shape of the part to be cast.

A metal alloy is melted, often in induction furnace, and poured into the preheated investment. After cooling, the shell is broken away, the metal parts are cut from the tree and gates and vents are ground off.

Our factory

Product detail pictures:

Related Product Guide:

We have advanced equipment. Our products are exported to the USA, the UK and so on, enjoying a good reputation among customers for Hot-selling Resin Sand Moulding - OEM Stainless Steel Casting with Investment Casting – Mingda , The product will supply to all over the world, such as: kazan, France, Mumbai, In the new century, we promote our enterprise spirit United, diligent, high efficiency, innovation, and stick to our policybasing on quality, be enterprising, striking for first class brand. We would take this golden opportunity to create bright future.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!