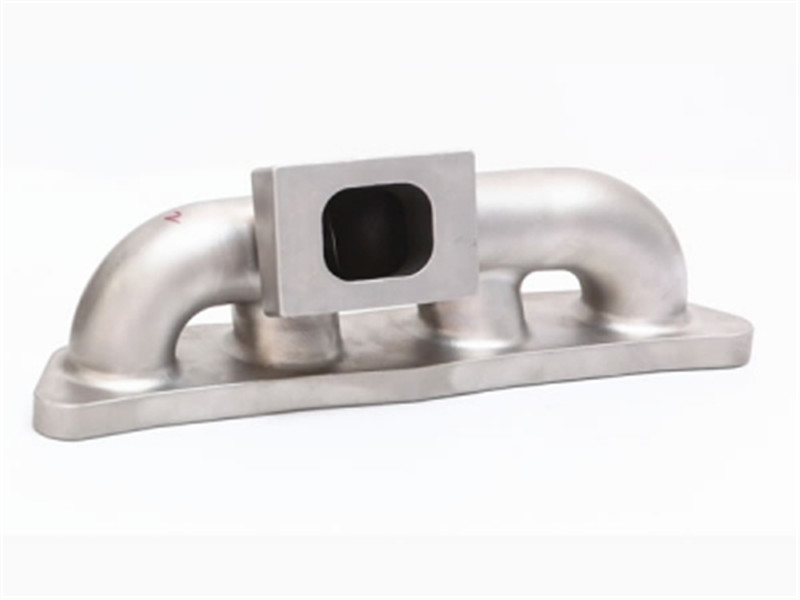

High reputation Static Pressure Line - Stainless Steel Casting Exhaust Manifold – Mingda

High reputation Static Pressure Line - Stainless Steel Casting Exhaust Manifold – Mingda Detail:

Basic Info

Casting Method: Thermal Gravity Casting

Process: Lost Wax Casting

Molding Technics: Pressure Casting

Application: Machinery Parts

Material: Stainless Steel

Surface Preparation: Polishing

Surface Roughness: Ra6.3

Machining Tolerance: +/-0.01mm

Standard: AISI

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 10 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

Stainless steel casting, also called stainless steel investment casting, refers to the formation of ceramics around a wax pattern to form a shell for casting stainless steel. Once wax patterns are created, they are melted into the gate system, immersed in slurry and sand to form a layered shell, and then replaced by molten stainless steel.

we provide custom stainless steel casting parts and components for industries and applications including automotive, food & dairy, machinery, medical, plumbing, watering, mining, petrochemical, electrical, energy, aerospace, submarine and others. We can assure you high quality stainless steel castings. The sizes of the stainless steel casting parts range from 0.1 inch up to 24 inches. The weights of the stainless steel casting parts are from an ounce to 50 pounds. Typical tolerances are ± .005″ per inch.

Advantages of Stainless Steel Casting

- Sizes: 0.1 in to 24 in

- Weights: a few grams to more than 50 pounds

- Surface: very smooth finish

- Tight tolerances

- Reliable process controls and repeatability

- Design and casting versatility

- Efficient production

- Affordable tooling

- Material variety

Stainless steel casting material:

304, 316, 304L/316L,

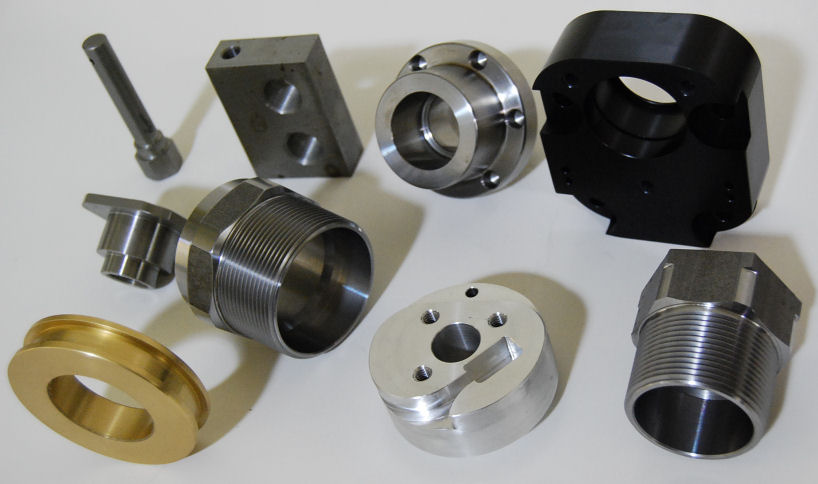

Secondary Operations and Treatment of Stainless Steel Casting We Offer

- High precision machining

- Polished zinc plating, nickel plating, electroplating, chrome plating

- Anodizing, phosphating, acid treatment, polishing

- Broaching, milling, drilling, tapping

- Surface grinding, sand blasting, powder coating

- Heat treatment

Products show

Product detail pictures:

Related Product Guide:

Well-run gear, qualified revenue workforce, and superior after-sales companies; We've been also a unified huge loved ones, anyone persist with the organization benefit unification, determination, tolerance for High reputation Static Pressure Line - Stainless Steel Casting Exhaust Manifold – Mingda , The product will supply to all over the world, such as: Latvia, Niger, Congo, If any product meed your demand, please feel free to contact us. We're sure your any inquiry or requirement will get prompt attention, high-quality products, preferential prices and cheap freight. Sincerely welcome friends all over the world to call or come to visit, to discuss cooperation for a better future!

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.