High Quality Metal Stamping Parts - Stainless Steel Metal Stamped Part – Mingda

High Quality Metal Stamping Parts - Stainless Steel Metal Stamped Part – Mingda Detail:

Basic Info

Type: Cold Stamping

Processing Type: Shaping Metal

Material: Stainless Steel

Mould: Multistep Progressive Dies

Surface Processing: Electroplating

Fine Blanking: Open

Process: Forming Process

Industry: Metal Stamping Parts

Tolerances: 0.01mm

Customized: Customized

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

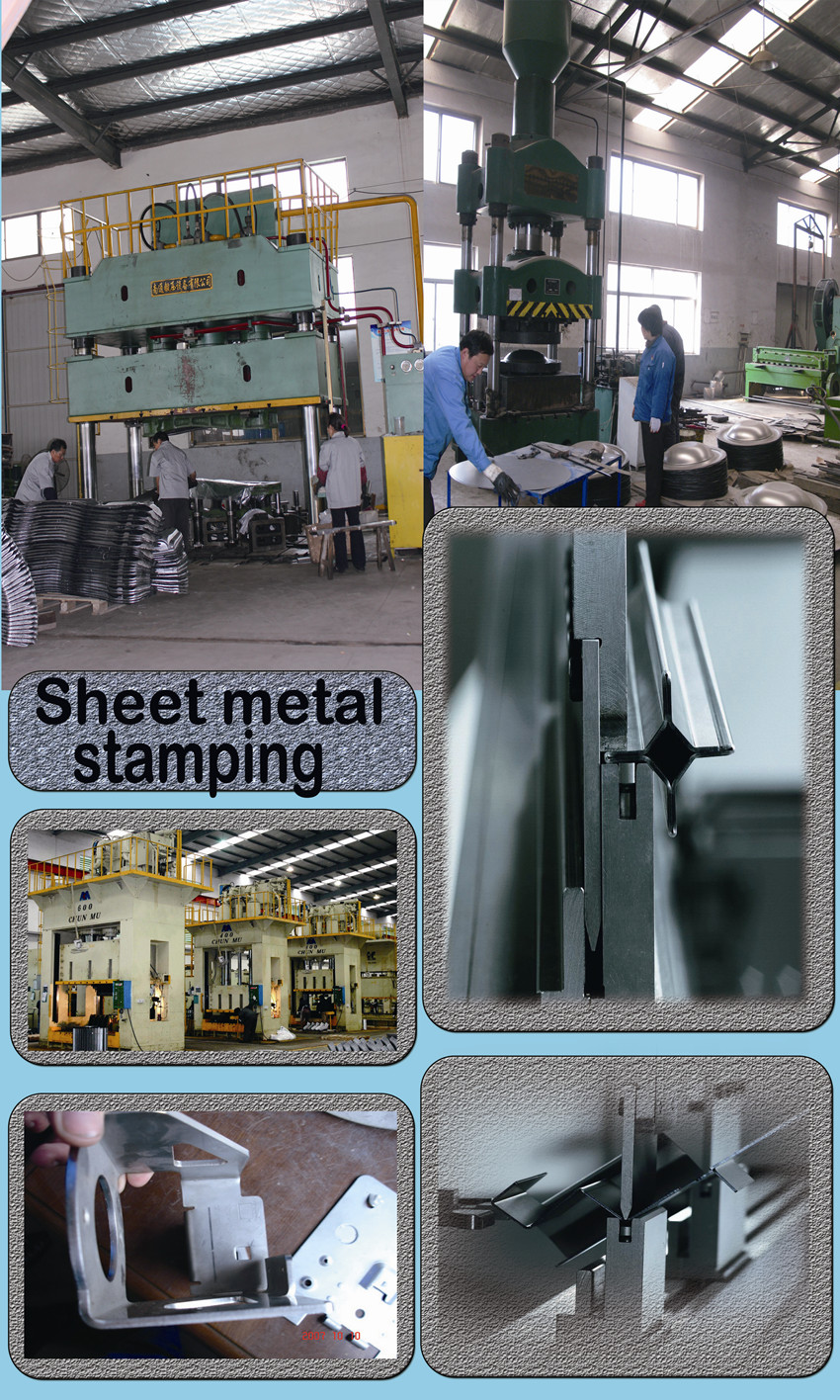

Hebei Mingda utilizes leading tooling, precision metal stamping, deep-drawn, machining, and cold forming,etc with sizes ranging from 5 tons - 350 tons.

Materials used in the precision metal stamping process include Stainless Steel, Aluminum, Copper and Cold Rolled Steel with thickness ranging from 0.002″ to 0.180″.

As a result, we have the capability to provide metal stamping services and products for a wide variety of industries.

Stamping parts have high strength

The parts are light weight and good rigidity, and after the plastic deformation of the sheet metal, the internal structure of the metal is improved, and the strength of the stamping parts is improved.

High dimensional accuracy

It has high dimensional precision, uniform size and good interchangeability.

The surface of the material is free from damage

The surface of the material is not damaged, so the utility model has better surface quality and smooth appearance, which provides convenient conditions for surface painting, electroplating, phosphating and other surface treatment.

Products show

Product detail pictures:

Related Product Guide:

Being supported by an state-of-the-art and skilled IT team, we could supply technical support on pre-sales & after-sales service for High Quality Metal Stamping Parts - Stainless Steel Metal Stamped Part – Mingda , The product will supply to all over the world, such as: Angola, India, USA, With the first-class products, excellent service, fast delivery and the best price, we have won highly praise foreign customers'. Our products have been exported to Africa, the Middle East, Southeast Asia and other regions.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.