High Quality for Smc Manhole Cover - High Precision Lost Wax Steel Casting – Mingda

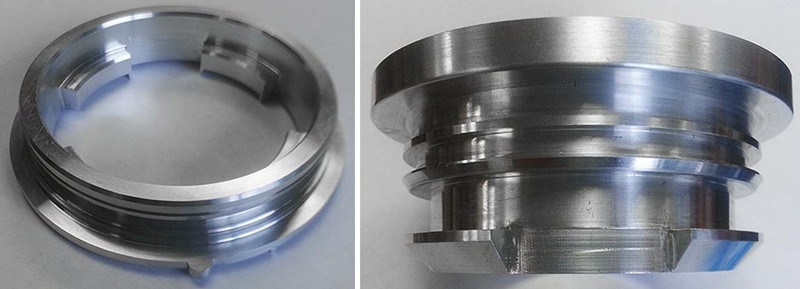

High Quality for Smc Manhole Cover - High Precision Lost Wax Steel Casting – Mingda Detail:

Basic Info

Casting Method: Thermal Gravity Casting

Process: Lost Wax Casting

Molding Technics: Pressure Casting

Application: Machinery Parts

Material: Stainless Steel

Surface Preparation: Polishing

Surface Roughness: Ra6.3

Machining Tolerance: +/-0.01mm

Standard: AISI

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

Stainless Steel is a steel alloy with a minimum of 10.5% chromium content by mass. Stainless steel is used where both the properties of steel and corrosion resistance are required. So like other cast steel alloys, stainless steel is widely used material for casting production.

Stainless steel casting made in our steel foundry is mainly by silical sol casting process. Silica sol casting is the most precision investment casting process. Stainless steel casting process involves melting of metal, molding, and creating quality components with constant heating or cleaning. When normal casting components are not able to deliver enough strength and shock resistant features then stainless steel castings are just taken wonderful choice over others. This process can produce high precision net shape castings with no machining. Normally we can control such precision stainless steel casting with tolerance CT5-6 level. Another advantage is that, with this process, our foundry can supply stainless steel casting with no defects.

Common Material Grades of Stainless Steel Casting

SS304: The most widely used austenite steel, may be referred to as A2 stainless.

SS316: The second most common austenite steel, also referred to as A4 stainless. SS316 is used primarily for its increased resistance to corrosion.

SS304L & SS316L (superaustenitic stainless steel): The [L” means that the carbon content of the alloy is below 0.03%, which reduces the sensitization effect caused by the high temperatures involved in welding. Compare with 300 series, it shows better resistance to stress-corrosion cracking.

17-4 PH: Most common precipitation-hardening martensitic stainless steel, which uses about 17% chromium and 4% nickel.

Surface Treatments of Stainless Steel Castings

Shot Blasting: Used to remove surface black oxide skin after casting of stainless steel products.

Pickling & Passivation Treatment: Pickling is a chemical treatment way to eliminate surface dirts like oxide skin, rust, welding spots,ect. And passivation is a process that forming a new abundant chromium protective layer, thus to improve the anti-oxidation ability of stainless steel castings.

Electropolishing: Used to remove surface tiny burrs and improve the brightness of stainless steel castings.

Mirror Polishing: A kind of surface polishing way that can achieve a smooth and shining surface like a mirror finish.

Application of Stainless Steel Castings

For the unique physical properties of stainless steel, Stainless steel castings are served for a wide range of industries, especially those in severe environments. Below are the main applications of stainless steel casting

our factory

Product detail pictures:

Related Product Guide:

While using the Client-Oriented organization philosophy, a rigorous top quality command process, highly developed production devices and a potent R&D workforce, we normally provide high quality products, outstanding solutions and aggressive charges for High Quality for Smc Manhole Cover - High Precision Lost Wax Steel Casting – Mingda , The product will supply to all over the world, such as: Sri Lanka, Argentina, French, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we will continue to develop, to provide the high-quality products and services, and promote lasting cooperation with our customers, common development and create a better future.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly