Good Quality Stainless Steel Stamped Parts - OEM Sheet Metal Precision Stamping Part – Mingda

Good Quality Stainless Steel Stamped Parts - OEM Sheet Metal Precision Stamping Part – Mingda Detail:

Basic Info

Type: Cold Stamping

Processing Type: Shaping Metal

Material: Copper

Mould: Multistep Progressive Dies

Surface Processing: Polishing

Fine Blanking: Open

Process: Forming Process

Industry: Metal Stamping Parts

Tolerances: 0.01mm

Customized: Customized

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

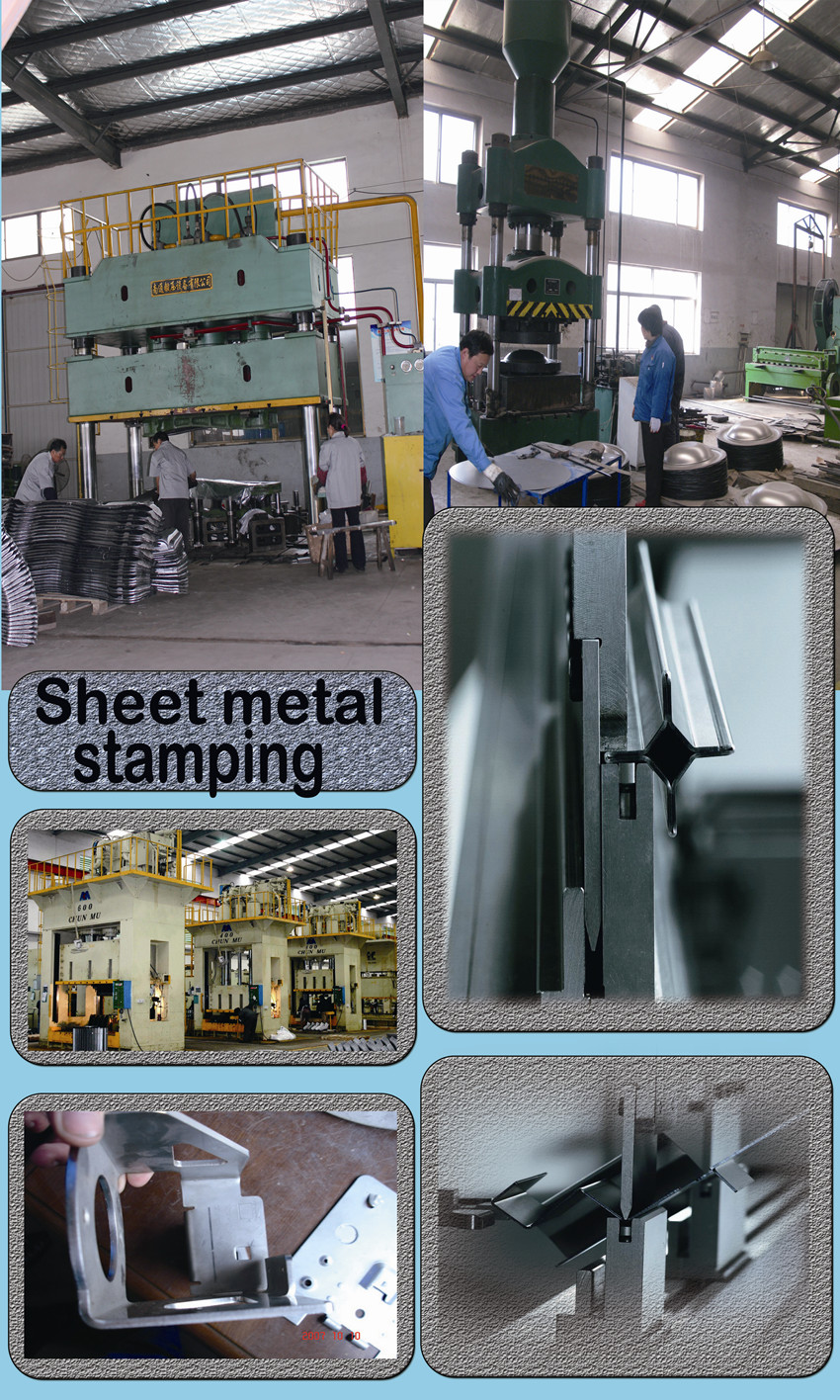

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape, Metal stamping is an integral part of electronics manufacturing process. Capability inGoldconn for variety of parts.

A) Small,medium and large size, press pressure range from 45T-630T.

B) The material: copper alloy, steel alloy, aluminium alloy-etc are available, thickness up to 3mm.

C) The surface treatment: plating, liquid painting, powder coating, anodizing, chromate-etc are available.

D) In house tooling design and fabrication, tooling modification, engineering service and maintenance.

E) Products are usually in industry, communication, medical, and automobile application.

Our service

1. We are ODM&OEM, design according to your drawing.

2. Rich experience and good technology support( have engineers with more than 20 years experience).

3. Manufacturer and Trade Company.

4. Low MOQ is accepted.

5. 100% inspection before delivery.

6. Competitive price with high quality.

7. Convenient transportation (Tianjin, Qingdao, Ningbo, Shanghai…).

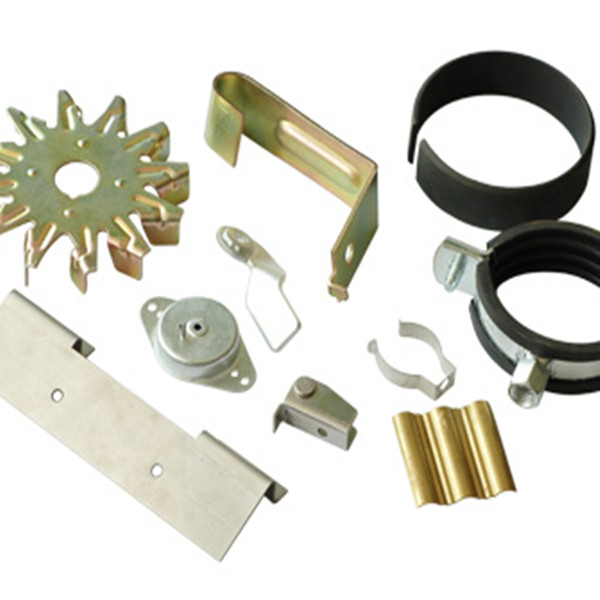

Products show

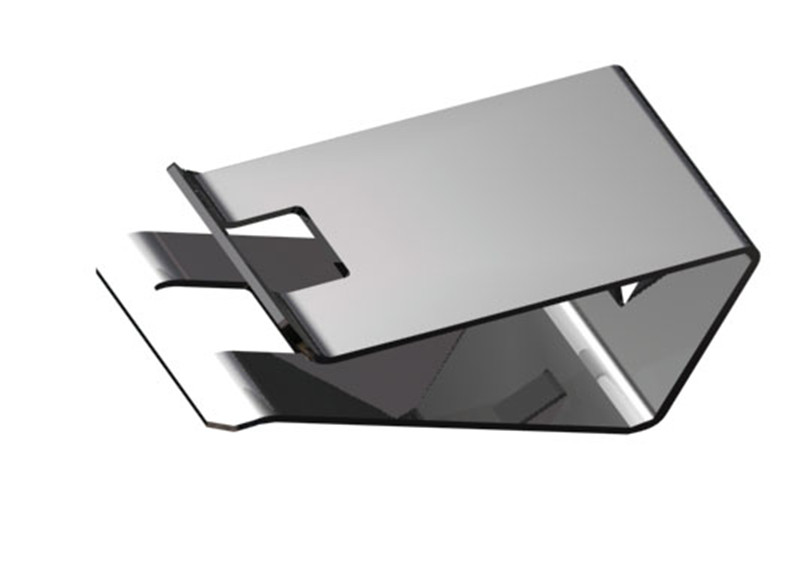

Product detail pictures:

Related Product Guide:

Each individual member from our large performance revenue crew values customers' needs and company communication for Good Quality Stainless Steel Stamped Parts - OEM Sheet Metal Precision Stamping Part – Mingda , The product will supply to all over the world, such as: Pretoria, Paraguay, Marseille, To meet the requirements of individual customers for each bit more perfect service and stable quality products. We warmly welcome customers around the world to visit us, with our multi-faceted cooperation, and jointly develop new markets, create a brilliant future!

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.