Good Quality Stainless Steel Stamped Parts - Custom Stainless Steel Punch Welding Part – Mingda

Good Quality Stainless Steel Stamped Parts - Custom Stainless Steel Punch Welding Part – Mingda Detail:

Basic Info

Type: Cold Stamping

Processing Type: Shaping Metal

Material: Stainless Steel

Mould: Multistep Progressive Dies

Surface Processing: Electroplating

Fine Blanking: Open

Process: Forming Process

Industry: Metal Stamping Parts

Tolerances: 0.01mm

Customized: Customized

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

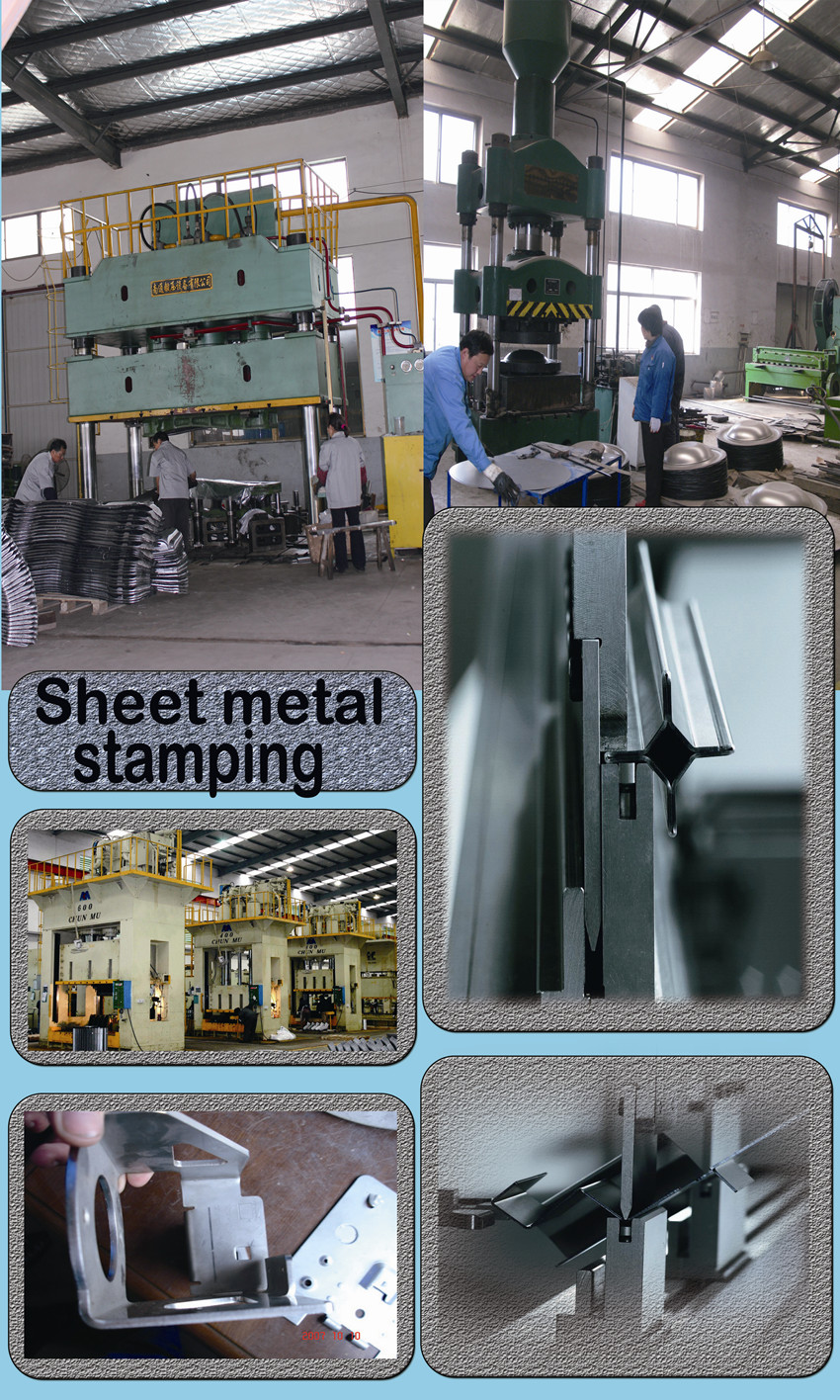

We are an ISO certficated approval metal stamping fabrication manufacturer from China mainland, our features service: sheet metal parts, metal stamping parts, sheet metal stamping, sheet metal punching, sheet metal press stamping parts, metal stamping , sheet metal oem stamping, sheet metal fabricated stamping, sheet metal precision stamping parts, sheet metal deep drawn stamping parts, cnc parts, cnc machining parts, cnc machined parts, cnc milling aluminum parts, cnc turning stainless steel parts, EDM cutting, wire cutting, etc…

Our equipment including Punching machine, hydraulic press, stretch machine, shears, bending machine, welding machine, laser cutting machine, painting production line,

phosphating production line, continuous die stamping production line ; universal testing machine, deep-drawing microscope, salt spray test machine, hardness tester,

thickness meter, sheet metal projectors.

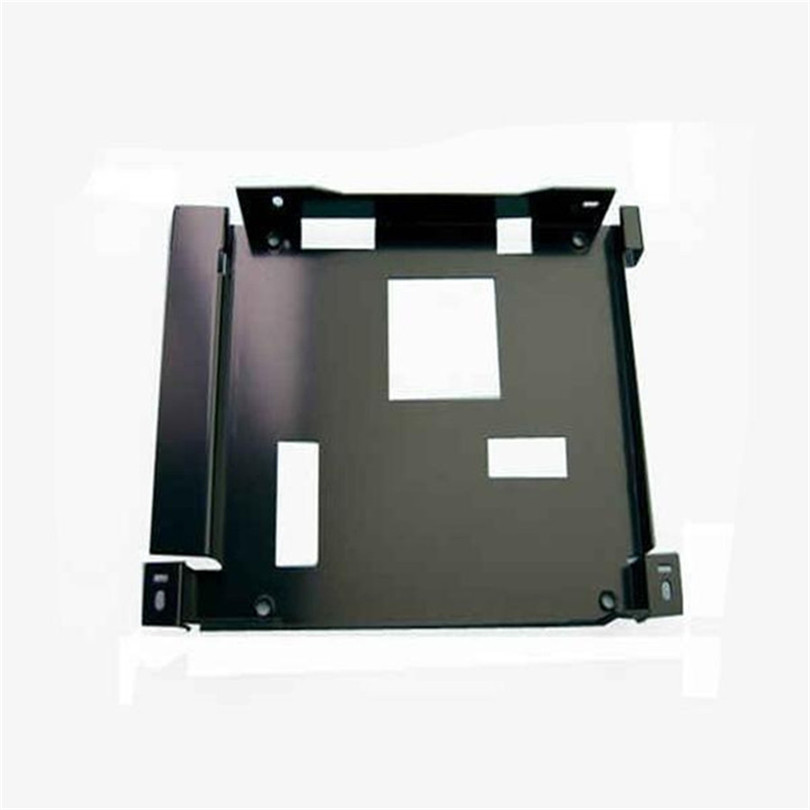

General product information

Material availableCarbon steel(CRS/SPCC,SECC,etc),Stainless steel, spring steel, Bronze(berylium,phosphor,etc), brass, copper alloy,aluminum alloy, tinplate,nickel silver, plastic

Surface treatment availablezinc/nickel/chrome/tin plating(colour or natural), Galvanization, anodizing, oil spraying, powder coating, polishing, passivate, brush,wire drawing,etc.

Metal processing availableStamping parts:tooling making, samples approval, cutting,stamping, punching,tapping,welding,bending and forming, finishing, assembly

CNC parts:CNC lathe milling, CNC lathe turning, drilling, tapping, finishing, assembly, packing

SpecificationOEM/ODM,make per customer’s drawing or sample

Package availablepolybag inside export carton outside or according customer’s requirement, blister and Tape and reel package available.

ToleranceStamping parts:0.01-0.1mm, CNC machining parts:0.1-0.002mm

Service availableBefore mass production, we supply pre-production samples for customer final confirmation, tooling maintenance and tooling slight change free

Documents availableISO certificate, material SGS testing reports, products certificate, company SGS report, COC report

CertificateISO9001:2008 approval, SGS compliance

Products show

Product detail pictures:

Related Product Guide:

We insist on offering premium quality manufacturing with superior business concept, honest product sales as well as finest and fast assistance. it will bring you not only the good quality product or service and huge profit, but the most significant is to occupy the endless market for Good Quality Stainless Steel Stamped Parts - Custom Stainless Steel Punch Welding Part – Mingda , The product will supply to all over the world, such as: UK, Paraguay, Qatar, Our expert engineering team will generally be prepared to serve you for consultation and feedback. We are able to also offer you with free of charge samples to meet your requirements. Best efforts will likely be produced to provide you the best service and merchandise. When you are keen on our business and products, please speak to us by sending us emails or call us quickly. In an effort to know our products and company extra, you may come to our factory to view it. We will generally welcome guests from all over the world to our business to create business relations with us. Please feel cost-free to speak to us for small business and we believe we'll share the best trading experience with all our merchants.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.