Free sample for Lost Foam Casting - Aluminum Die Casting Vehicle Crankcase Housing – Mingda

Free sample for Lost Foam Casting - Aluminum Die Casting Vehicle Crankcase Housing – Mingda Detail:

Basic Info

Die Casting Machine Type: Cold Chamber Die Casting Machine

Die Casting Method: Precision Die Casting

Application: Machinery Parts

Machining: CNC Machining

Material: Aluminum

Surface Preparation: Polishing

Pressure Chamber Structure: Vertical

Tolerance Grade: 8

Casting Surface Quality Level: 3

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

Die casting is a manufacturing process that can produce geometrically complex metal parts through the use of reusable molds, called dies.

The die casting process involves the use of a furnace, metal, die casting machine, and die. The metal, typically a non-ferrous alloy such as aluminum or zinc, is melted in the

furnace and then injected into the dies in the die casting machine. There are two main types of die casting machines – hot chamber machines (used for alloys with low melting

temperatures, such as zinc) and cold chamber machines (used for alloys with high melting temperatures, such as aluminum).

The differences between these machines will be detailed in the sections on equipment and tooling. However, in both machines, after the molten metal is injected into the dies,

it rapidly cools and solidifies into the final part, called the casting. The steps in this process are described in greater detail in the next section.

The castings that are created in this process can vary greatly in size and weight, ranging from a couple ounces to 100 pounds.

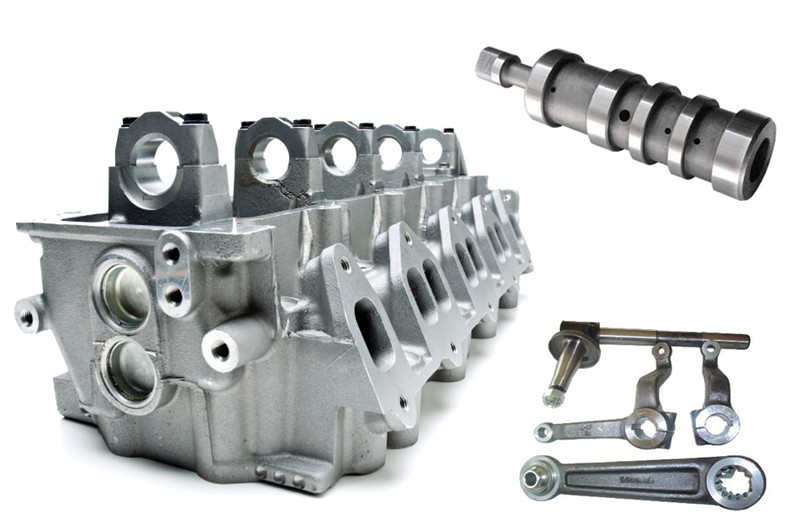

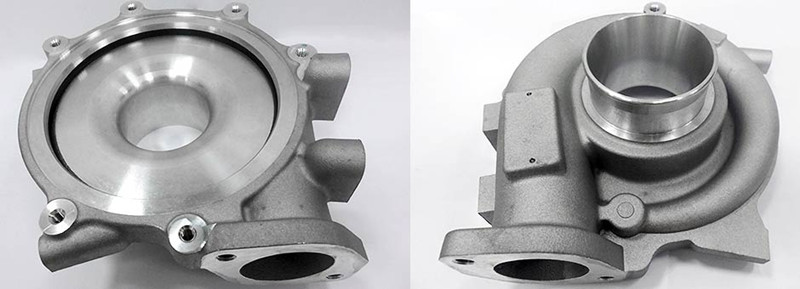

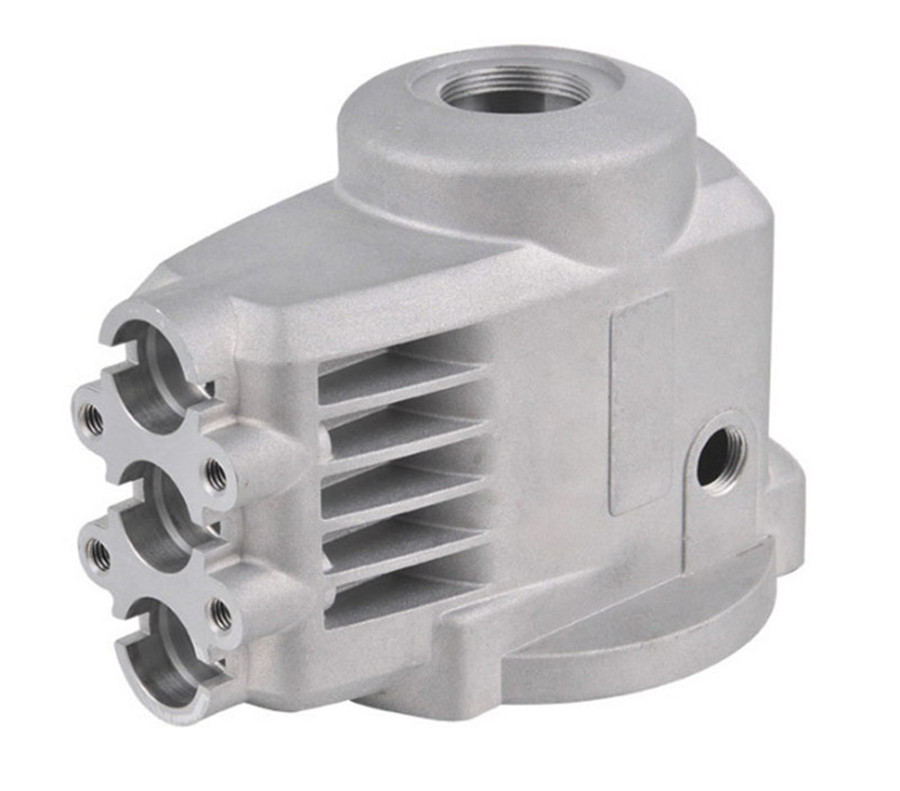

One common application of die cast parts are housings – thin-walled enclosures, often requiring many ribs and bosses on the interior. Metal housings for a variety of

appliances and equipment are often die cast. Several automobile components are also manufactured using die casting, including pistons, cylinder heads, and engine blocks.

Other common die cast parts include propellers, gears, bushings, pumps, and valves.

Products show

Product detail pictures:

Related Product Guide:

continue to enhance, to be certain solution top quality in line with market and buyer standard requirements. Our corporation has a excellent assurance program are actually established for Free sample for Lost Foam Casting - Aluminum Die Casting Vehicle Crankcase Housing – Mingda , The product will supply to all over the world, such as: Kuwait, Australia, Uganda, Customer satisfaction is our first goal. Our mission is to pursue the superlative quality, making continual progress. We sincerely welcome you to make progress hand in hand with us, and construct a prosperous future together.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.