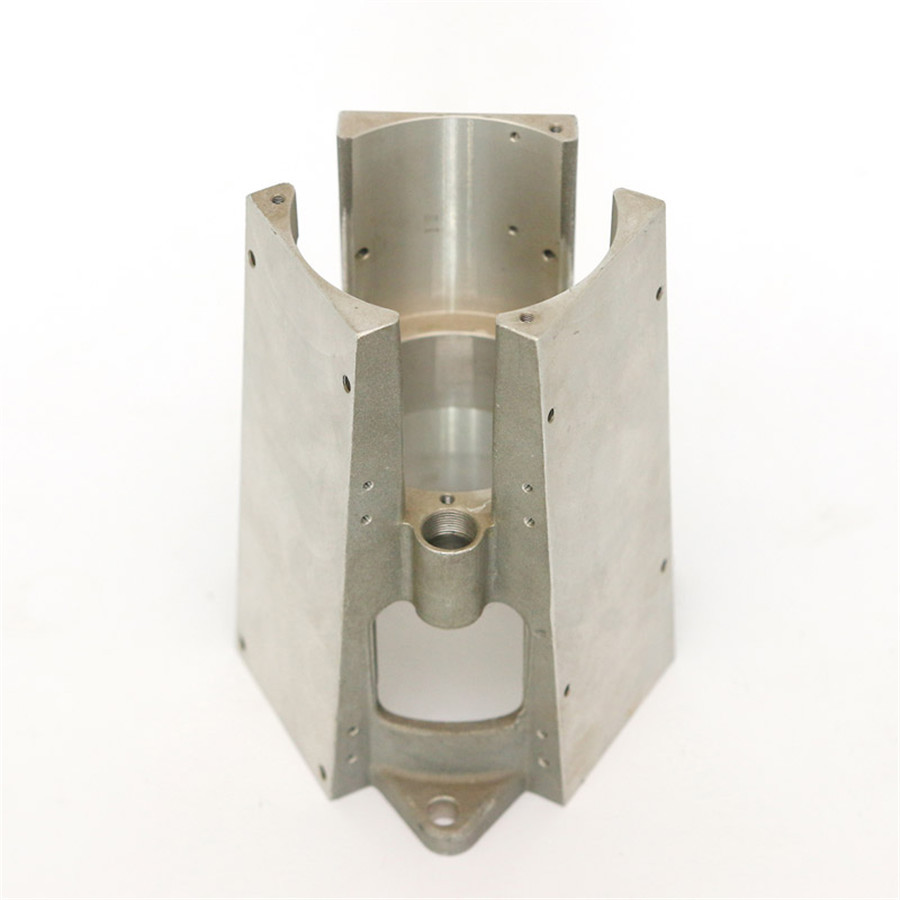

Factory Supply Automatic Moulding - OEM Custom Alloy Steel Casting Parts – Mingda

Factory Supply Automatic Moulding - OEM Custom Alloy Steel Casting Parts – Mingda Detail:

Product Description

Take your casting solutions to a whole new level with our lost wax investment castings. Investment castings are often known as lost wax casting, silica sol casting, precise casting or de-waxing casting, the materials used for casting process are vary widely.

The great part about casting is that there is no limit to product shape, size or structure, according to your unique, custom specifications. Investment casting is well known for lower machining allowance, closer tolerance control and better surface finish, which makes it very popular. Additionally, these castings are known to be of superior quality, making them highly in demand in the industry today.

We handle large or small orders and you need not worry about the quality of the finished product.

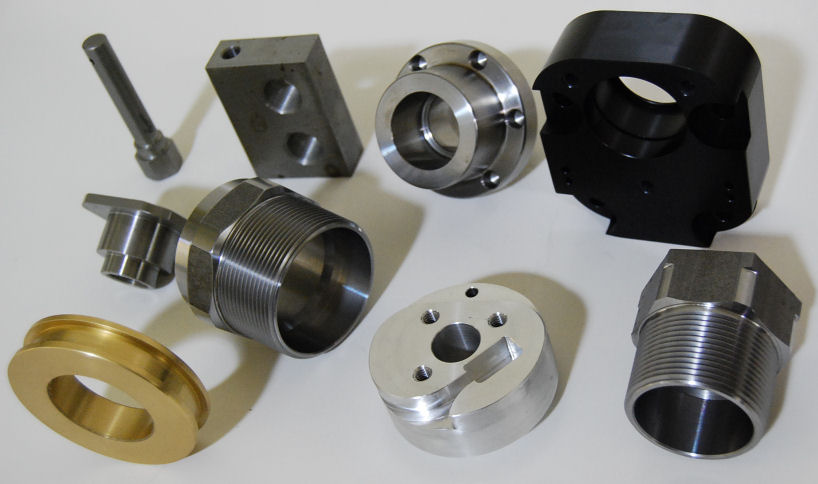

Stainless steel: 303/304/316/duplex2205/17-4PH/4340/ect

We handle many other type of materials.Please contact us if your required materials are not listed above.

Technology: precision casting, investment casting,silica sol casting,water glass casting

Surface treatment: Blacking, Polishing, Anodize, Chrome plating, Zinc plating,Nickel plating, Tinting, Power coating, E-coating etc

Professional precision manufacture for more than 13 years.

Molding process–Precision Casting

Material:– Carbon steel Alloy steel,stainless steel duplex2205,Standard:DIN ASTM

Possible Heat Treatment–Normalizing, tempering, hardening and tempering

Industry involved– pump&construction&Agricultural& Engineering& Automotive industry–..

Part Unit Weight range–0.01Kg~160kg

Wall thickness requirements–min 2mm

Manufacturer certification– ISO9001 (2008) TS16949:2009

Products show

Process

Our factory

Product detail pictures:

Related Product Guide:

Based on domestic market and expand abroad business is our progress strategy for Factory Supply Automatic Moulding - OEM Custom Alloy Steel Casting Parts – Mingda , The product will supply to all over the world, such as: Puerto Rico, Korea, Canada, It using the world's leading system for reliable operation, a low failure rate, it suitable for Argentina customers choice. Our company is situated within the national civilized cities, the traffic is very convenient, unique geographical and economic conditions. We pursue a people-oriented, meticulous manufacturing, brainstorm, build brilliant business philosophy. Strict quality management, perfect service, reasonable price in Argentina is our stand on the premise of competition. If necessary, welcome to contact us by our website or phone consultation, we'll be happy to serve you.

This company has the idea of better quality, lower processing costs, prices are more reasonable, so they have competitive product quality and price, that's the main reason we chose to cooperate.