Excellent quality Car Components Industry - OEM Precision Investment Casting for Machinery Part – Mingda

Excellent quality Car Components Industry - OEM Precision Investment Casting for Machinery Part – Mingda Detail:

Basic Info

Casting Method: Thermal Gravity Casting

Process: Lost Wax Casting

Molding Technics: Pressure Casting

Application: Machinery Parts

Material: Stainless Steel

Surface Preparation: Polishing

Surface Roughness: Ra6.3

Machining Tolerance: +/-0.01mm

Standard: AISI

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 10 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

Investment castings are typically selected because they can be produced with fine detail, excellent “as-cast” surface finish, shape into internal or external features, thin walls, and internal passageways to get to a near-net shape. This often leads to significant customer cost savings in material, labor and machining.

In lost wax investment casting, a sacrificial detailed wax pattern of the desired finished part is created and mounted onto a wax “tree”, which includes the metal delivery system (gates and risers). The tree is alternately dipped into a ceramic slurry and sprinkled with stucco material, and is allowed to dry. This process is repeated until a thick shell is created over the wax pattern. The wax pattern is melted out leaving a cavity in the shape of the pattern. The cavity is filled with molten metal. After solidification, the shell is broken away, the gating material removed, and the finished part remains. Check out the below video to learn more.

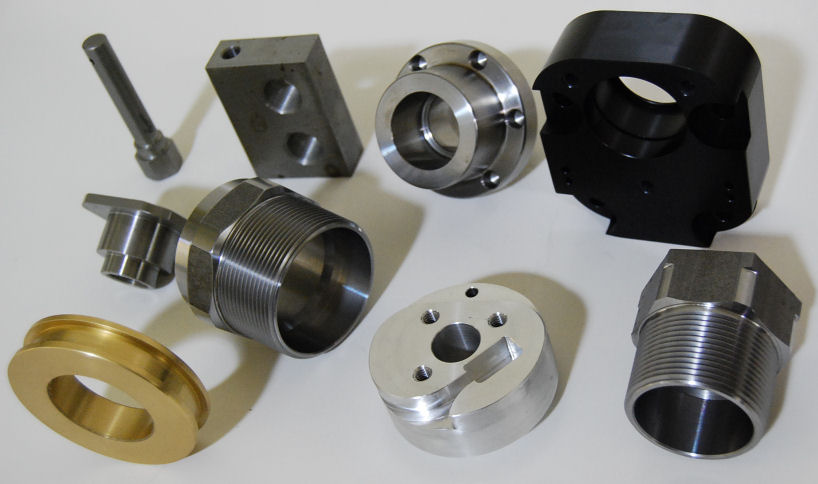

Products show

Process

Our factory

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Excellent quality Car Components Industry - OEM Precision Investment Casting for Machinery Part – Mingda , The product will supply to all over the world, such as: Bangladesh, Luxembourg, Hungary, We set a strict quality control system. We have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. Please feel free to contact us for further information if you have any questions. We are glad to work for every client.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly