Bottom price Iron Shell Sand Moulding - High Pressure Aluminum Die Casting Parts – Mingda

Bottom price Iron Shell Sand Moulding - High Pressure Aluminum Die Casting Parts – Mingda Detail:

Basic Info

Die Casting Machine Type: Cold Chamber Die Casting Machine

Die Casting Method: Precision Die Casting

Application: Machinery Parts

Machining: CNC Machining

Material: Aluminum

Surface Preparation: Polishing

Pressure Chamber Structure: Vertical

Tolerance Grade: 8

Casting Surface Quality Level: 3

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

Aluminium is the most abundant metal of all, as it makes up 8% of the Earth`s crust, and its non-magnetic and ductile properties allow it to have a wide range of applications. One of these applications is within alloys, with the most popular combinations including materials such as copper, zinc and magnesium. Aluminium alloys are created via the die casting process in order to improve the properties of the metal, mainly to increase its strength, since pure aluminium is relatively soft.

Aluminium alloys are used in many different industries, sectors and products, such as aerospace, automotive, military, transportation, packaging, food preparation and electrical components. Each aluminium alloy has its own specific properties, so it is vital that you choose the one that best suits your needs and your project`s requirements. Still, the different alloys have some aspects in common:

- Lightness

- Resistance to corrosion

- High levels of strength

- Electrical and thermal conductivity

- Suitable for surface treatments

- Recyclable

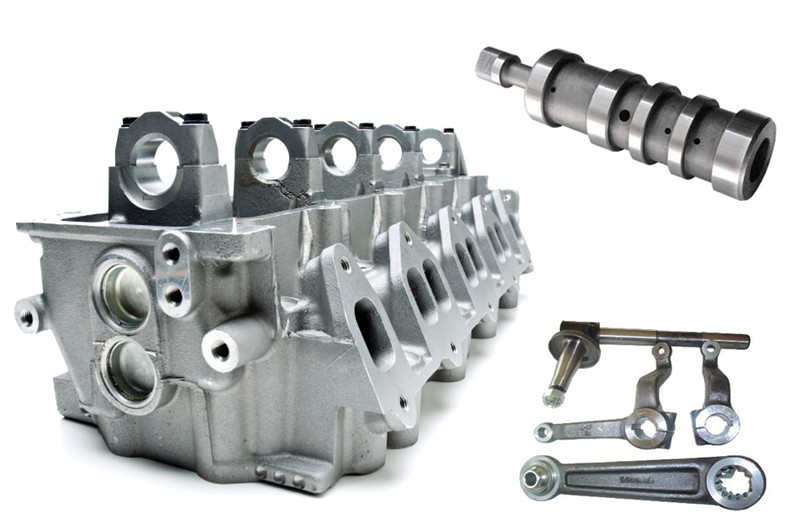

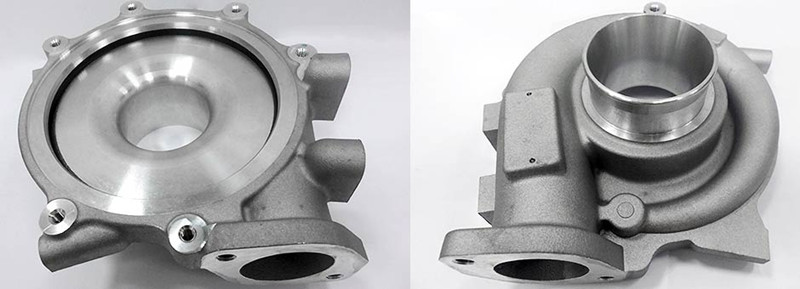

Products show

Product detail pictures:

Related Product Guide:

We keep on with our enterprise spirit of Quality, Efficiency, Innovation and Integrity. We intention to create extra worth for our buyers with our prosperous resources, superior machinery, experienced workers and superb services for Bottom price Iron Shell Sand Moulding - High Pressure Aluminum Die Casting Parts – Mingda , The product will supply to all over the world, such as: Costa Rica, Muscat, South Africa, In the new century, we promote our enterprise spirit United, diligent, high efficiency, innovation, and stick to our policybasing on quality, be enterprising, striking for first class brand. We would take this golden opportunity to create bright future.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,