8 Year Exporter Aluminum Gravity Casting - Stainless Lost Wax Casting for Machinery Part – Mingda

8 Year Exporter Aluminum Gravity Casting - Stainless Lost Wax Casting for Machinery Part – Mingda Detail:

Basic Info

Casting Method: Thermal Gravity Casting

Process: Lost Wax Casting

Molding Technics: Pressure Casting

Application: Machinery Parts

Material: Stainless Steel

Surface Preparation: Polishing

Surface Roughness: Ra6.3

Machining Tolerance: +/-0.01mm

Standard: AISI

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 10 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

Lost-wax process, also called cire-perdue, method of metal casting in which a molten metal is poured into a mold that has been created by means of a wax model. Once the mold is made, the wax model is melted and drained away. A hollow core can be effected by the introduction of a heat-proof core that prevents the molten metal from totally filling the mold. Common on every continent except Australia, the lost-wax method dates from the 3rd millennium BC and has sustained few changes since then.

To cast a clay model in bronze, a mold is made from the model, and the inside of this negative mold is brushed with melted wax to the desired thickness of the final bronze. After removal of the mold, the resultant wax shell is filled with a heat-resistant mixture. Wax tubes, which provide ducts for pouring bronze during casting and vents for the noxious gases produced in the process, are fitted to the outside of the wax shell, which may be modeled or adjusted by the artist. Metal pins are hammered through the shell into the core to secure it. Next, the prepared wax shell is completely covered in layers of heat-resistant plaster, and the whole is inverted and placed in an oven. During heating, the plaster dries and the wax runs out through the ducts created by the wax tubes. The plaster mold is then packed in sand, and molten bronze is poured through the ducts, filling the space left by the wax. When cool, the outer plaster and core are removed, and the bronze may receive finishing touches.

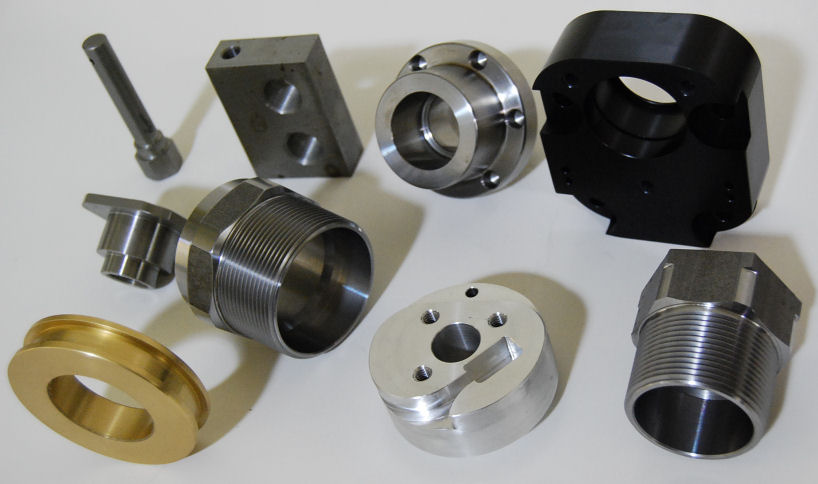

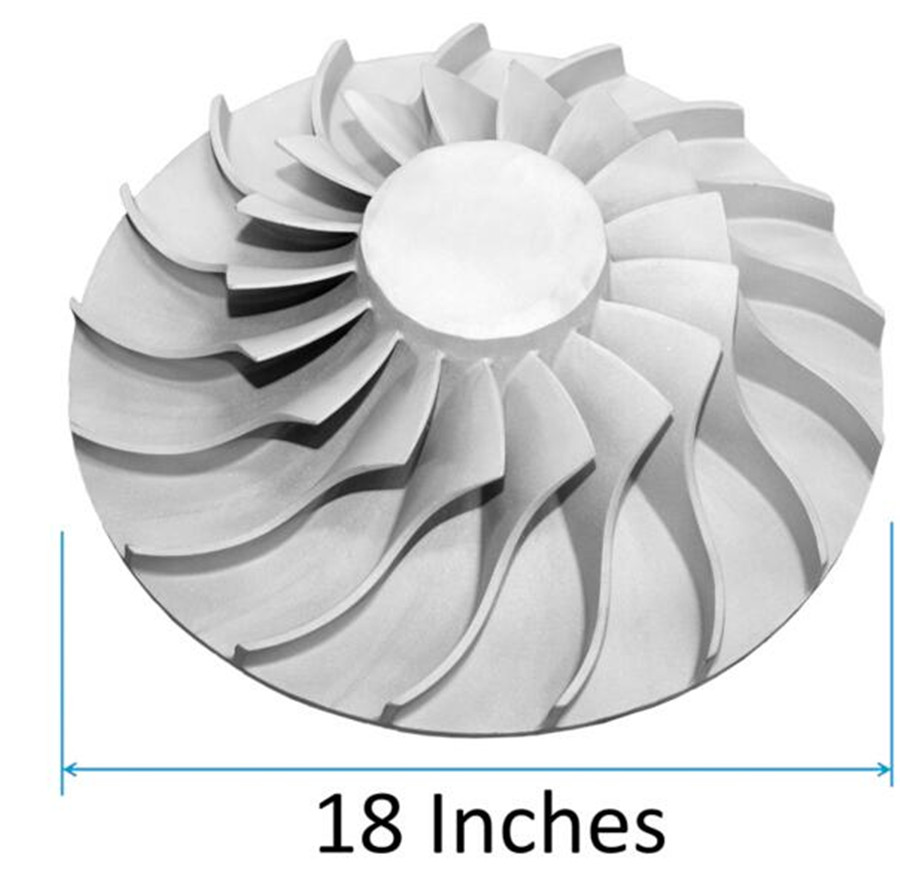

Products show

Process

Our factory

Product detail pictures:

Related Product Guide:

We have state-of-the-art equipment. Our products are exported for the USA, the UK and so on, enjoying a fantastic status among the clients for 8 Year Exporter Aluminum Gravity Casting - Stainless Lost Wax Casting for Machinery Part – Mingda , The product will supply to all over the world, such as: Islamabad, Bolivia, Sierra Leone, We have more than 10 years experience of production and export business. We always develop and design kinds of novel products to meet the market demand and help the guests continuously by updating our products. We are specialized manufacturer and exporter in China. Wherever you are, please join us, and together we will shape a bright future in your business field!

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.