Informații de bază

Aplicație: Auto and Motorcycle Accessory

Standard: ASME

Tratament de suprafață: Lustruire

Tip de producție: Producţie în masă

Metoda de prelucrare: CNC Milling

Material: Oţel

Dimensiune: Conform desenului

Informații suplimentare

Ambalaj: pachet standard de export

Productivitate: 10 Ton/Month

Marca: Mingda

Transport: Ocean, Pământ, Aer

Locul de origine: China

Certificat: ISO9001

Port: Tianjin

Descriere produs

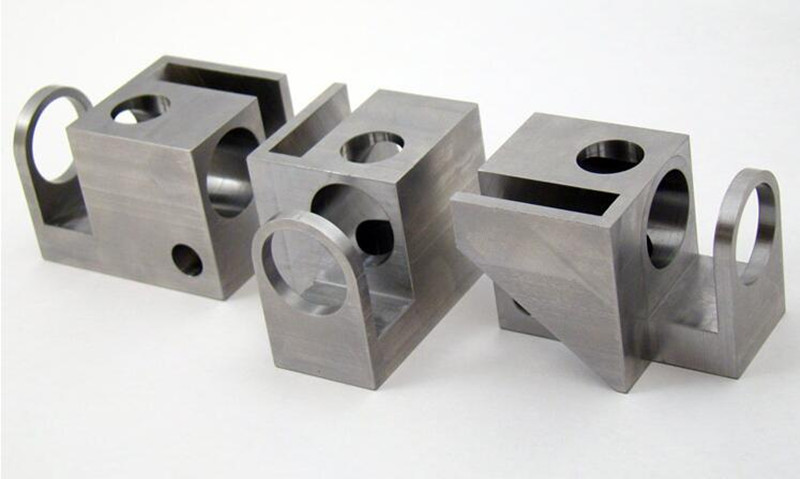

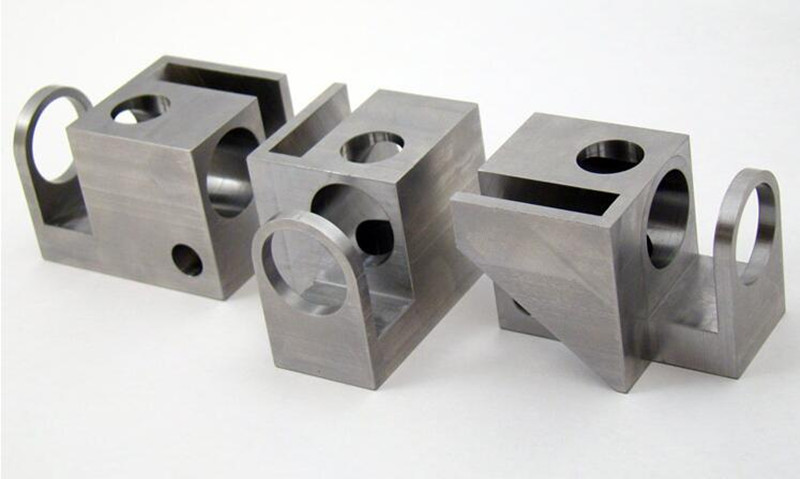

CNC milling is the process of rotating a cutting tool in a spindled axis to produce a shape or form. The cutting tool is controlled by a specialized computer, which greatly increases reliability and repeatability, while reducing the potential for human error. Most milling machines are equipped with tool changers, which allow the machine to automatically switch between a variety of cutting tools.

Because of this, CNC milling is often referred to interchangeably as CNC machining, because both encompass a variety of operations that can be done within a CNC machining center. CNC milling also encompasses drilling, reaming, threading, tapping, and other operations, as they can be completed in the same setup.

With various tooling and ingenuity, CNC milling is capable of producing almost any shape. The wide range of potential milling applications also makes CNC machining the most variable service offers. Tolerance, surface finish, part size, tooling, and material properties can all directly affect pricing.

Whether a part is suited for 3-, 4-, or 5-axis milling depends greatly upon the dimensions and features of the part itself. In general, fewer setups are needed for milling machines with more axis. Completing as much geometry as possible in a single setup ensures greater feature-to-feature accuracy, as the machine`s zero remains the same.

Multiple-axis machinery requires complex, skillful, and meticulous programming. Providing a 3D CAD file can generally reduce time spent quoting or programming CNC milling code.

+/- 0.0005″ TOLERANCE

STAMPING DIES & MOLDS

ALL METALS/ALLOYS/PLASTICS

3-, 4-, & 5-AXIS MACHINING