Materiaal: roestvrij staal

Oppervlaktevoorbereiding: Polijsten

Oppervlakteruwheid: Ra6.3

Bewerkingstolerantie: +/-0,01 mm

Standaard: AISI

Certificering: SGS, ISO 9001:2008

Maat: volgens tekening

Aanvullende informatie

Verpakking: standaard exportverpakking

Productiviteit: 10 ton/maand

Merk: Mingda

Transport: zee, land, lucht

Plaats van herkomst: China

Certificaat: ISO9001

Haven: Tianjin

Productomschrijving

Metal Casting Basics

Metal investment casting provides the opportunity to produce a near limitless variety of shapes from almost any alloy. Metal Casting also allows for the addition of virtually unlimited features that can be incorporated right into the mold.

When producing highly complex, intricate parts or assemblies, no other fabrication technique can equal the cost-performance superiority of metal investment casting.

Design Freedom and Versatility

With more than 120 different ferrous and non-ferrous casting alloys available, Mingda can produce metal castings using virtually any metal for unlimited metal investment casting applications. The metal investment casting process is very versatile and produces a wide range of metal cast assemblies for a range of industries. Investment cast metal parts provide the maximum design flexibility for manufacturing complex, one-part structures.

The initial wax injection mold used to produce the metal casting patterns, averaged over the part volume, is often lower that other manufacturing tooling costs. Mingda produces its molds

in-house and maintains them free of charge for the life of the program. In relation to long-term benefits a quality tool produces a quality part and thus will be more cost efficient in the long run. Mingda uses the latest solidification software technology and innovative practices to ensure consistent and precise wax patterns to make your cast metal parts.

Reliability is engineered into every metal cast part. The metal investment cast process at Aero Metals is tracked through a state-of-the-art ERP system, monitoring our production to ensure quality and reliable metal casting through put and process controls. We also adhere to our certified ISO quality procedures to deliver repeatability from lot to lot.

Metal investment casting is produced from wax patterns, which are reclaimed, cleaned, and reused time and time again. The wax pattern is used to pre-qualify the metal casting for the part, which reduces metal scrap. More importantly, the metal investment casting process produces parts to net- or near-net shape, which significantly reduces, or eliminates, secondary machining waste. Any metal casting scrap can also be re-melted, tested, and poured again. Metal casting is a very green and eco-friendly process.

Unlike many other casting production methods, metal investment castings do not require any draft. The design engineer is free to incorporate such features as under-cuts, logos, numbers, and letters into the metal casting component. In addition, through holes, slots, blind holes, external and internal splines, gears, and thread profiles can be cast to reduce secondary machining time and total part cost. Give us a call and we would be happy to consult with you on your project and provide design assistance for the metal investment cast manufacturing process.

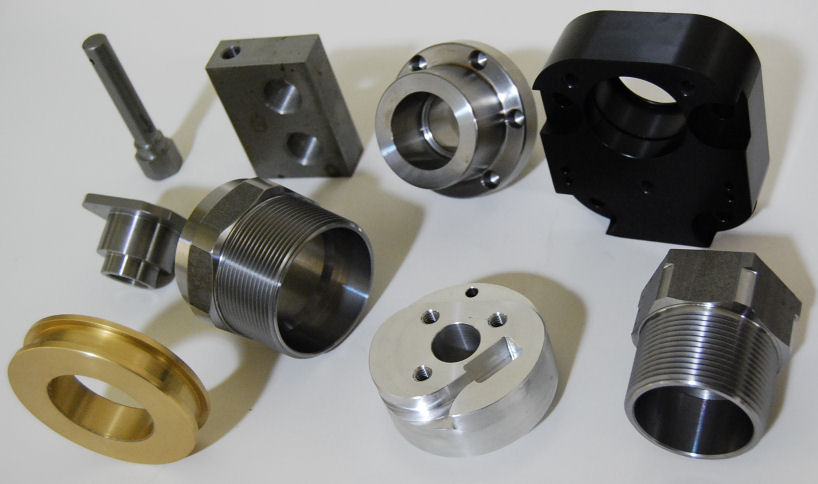

Products show

Process

Onze fabriek