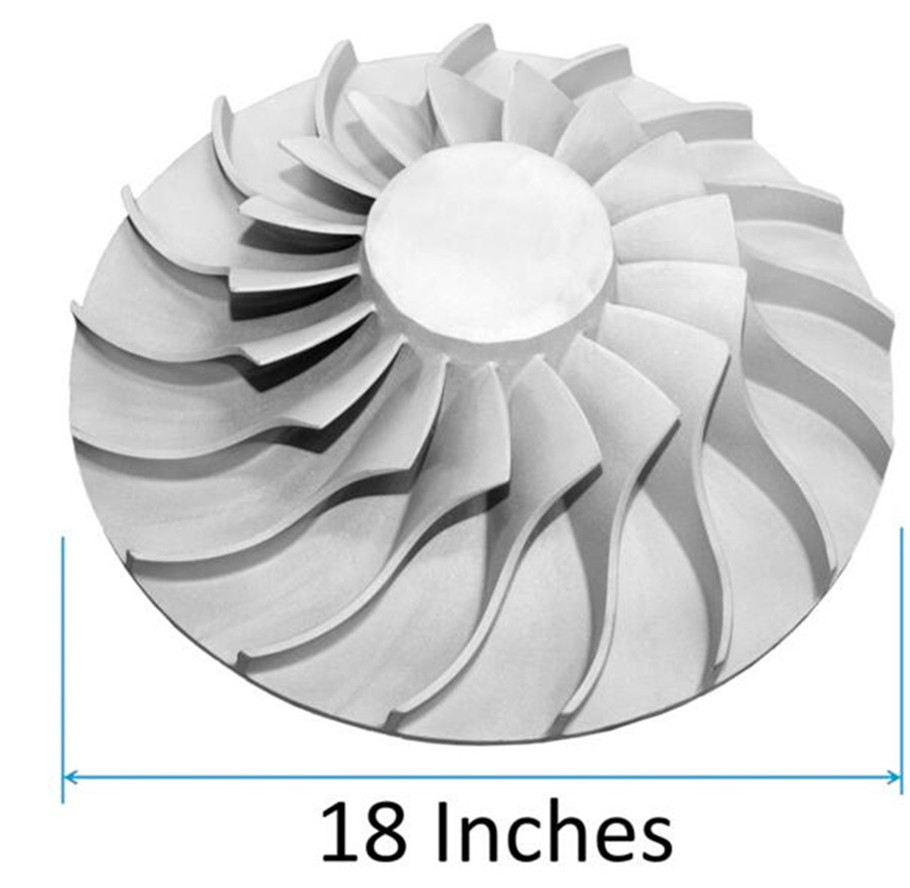

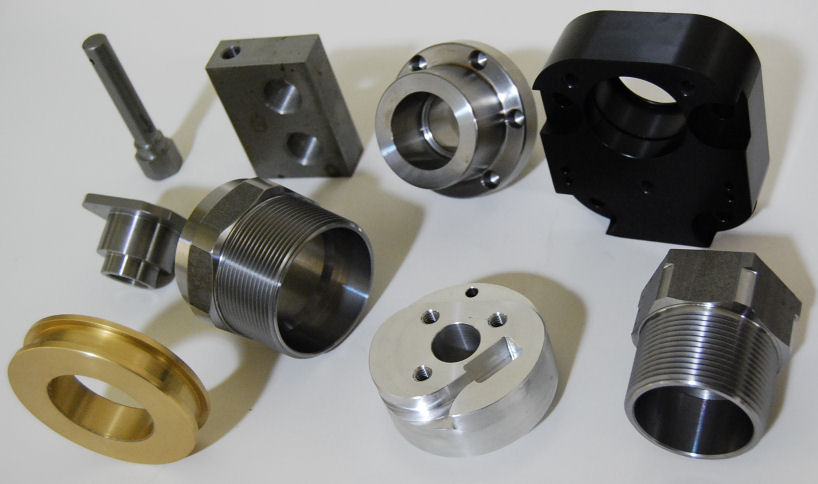

Product Description

The investment casting process or lost wax process, can produce the most intricate shapes in just about any alloy. In order to produce & machine these parts, you need to have in depth knowledge of the alloys and much experience…both of which Thompson Investment Casting possesses. There is no other metal working process that provides the design freedom to easily cast complex intricate shapes and assemblies as the investment casting process. The lost wax method out performs any other casting process when it comes to superior surface finishes especially when compared to sand casted, forged or welded fabrications. Some specific benefits are:

Reliability

The investment casting process provides reliable process controls and repeatability that are maintained from casting to casting.

Tolerances

Hebei Mingda routinely holds to tolerances of ± .005″. This is not always possible with other types of casting processes.

Amortization Lowers Tooling Cost

The initial wax injection mold to produce the patterns, averaged over the entire production quantity, is often lower than other casting tooling costs. Quality tooling produces a quality part and will be more cost efficient in the long run.

Intricate Design

When using investment castings, design engineers can easily incorporate features such as logos, product ID’s/numbers, and letters into their component. Thru holes, slots, blind holes, external and internal splines, gears, and thread profiles can often be cast to reduce secondary machining time and total part cost.

Products show

Process

Our factory