Stainless Steel Precision Casting in Investment Casting

Product Description

Investment casting company in China casting industry – Hebei Mingda uses precision lost wax investment casting process and machining & surface treatment technical to produce thousands of metal silica sol lost wax casting parts with the materials carbon steel, stainless steel, heat resistant steel, alloy steel, low alloy steel, super alloy, aluminum alloy, copper alloy, high chromium cast iron and ductile iron.

Mingda is one experienced castings manufacturer who uses the lost wax – silica sol shell craft (the quality of this kind of castings better than the water glass craft castings) and Mingda is good at producing the complex metal precision castings.

Mingda lost wax casting process & machining perform ISO 9001:2008, ISO/TS 16949 and ISO14001-2004 strictly to guarantee the customers’ requirements.

Mingda silica sol lost wax investment casting process and machining with an output 80 tons per month precision metal castings including lost wax castings,

precision machining parts and surface treatment metal products exports to all over the world.

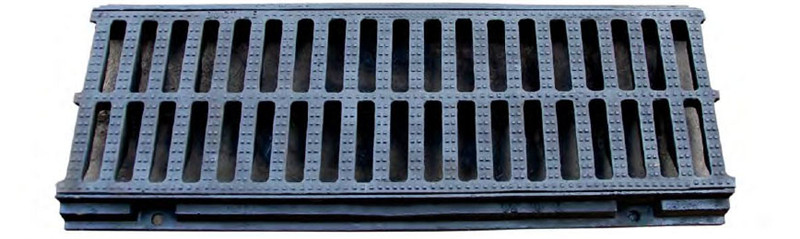

Products show