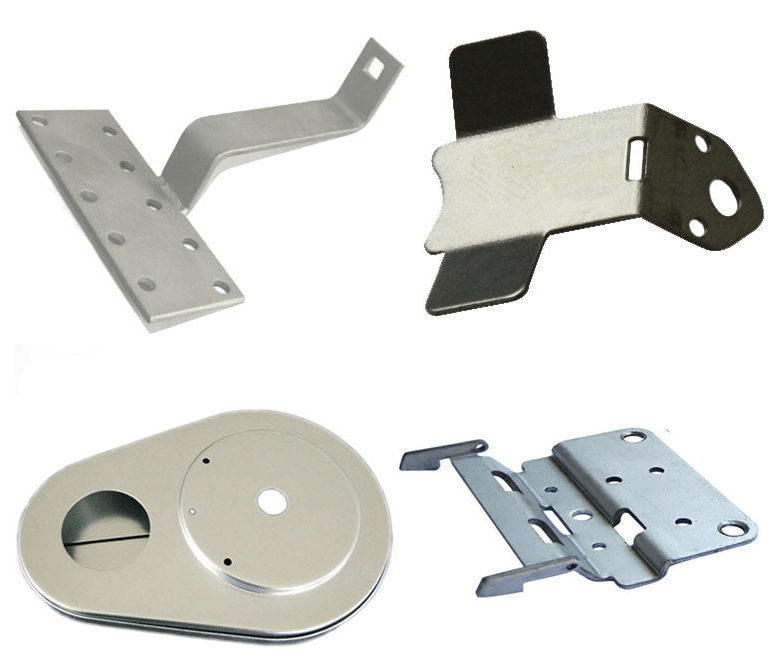

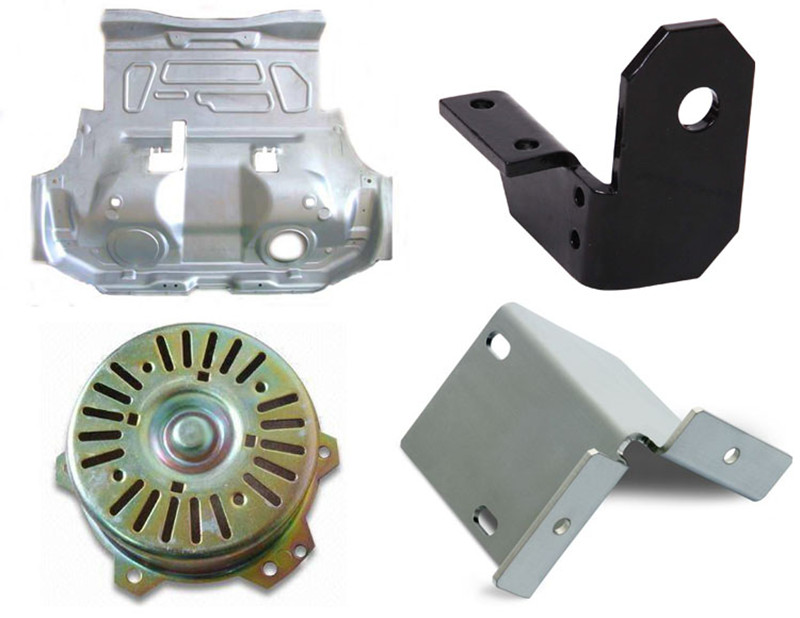

OEM Stainless Steel Metal Stamping Part

Basic Info

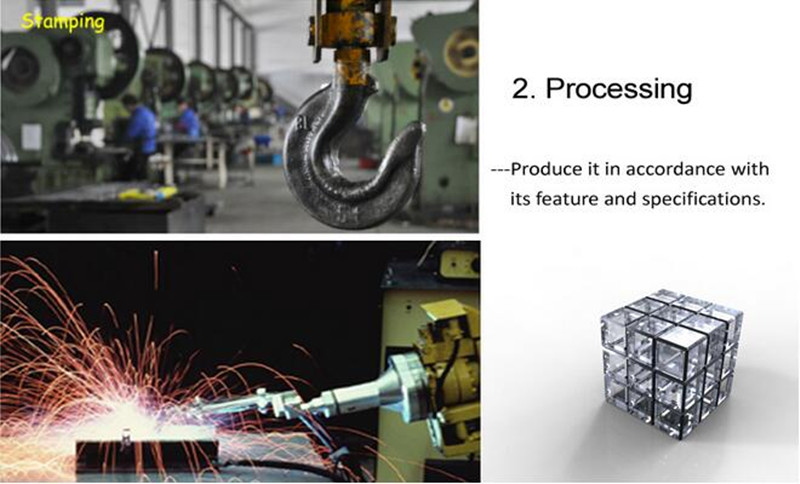

Type: Cold Stamping

Processing Type: Shaping Metal

Material: Stainless Steel

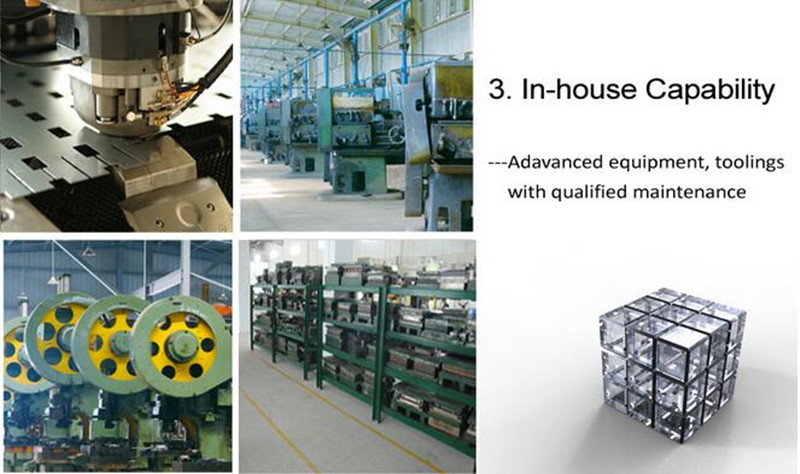

Mould: Multistep Progressive Dies

Surface Processing: Polishing

Fine Blanking: Open

Process: Forming Process

Industry: Metal Stamping Parts

Tolerances: 0.01mm

Customized: Customized

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

Mingda metal stamping service combines the experience of our toolmakers with our dedication to quality to produce parts that reliably meet our clients’ standard. Using progressive tooling and secondary tooling to produce small and large parts, we are able to offer quick turnarounds on prototypes and production runs.

Capabilities:

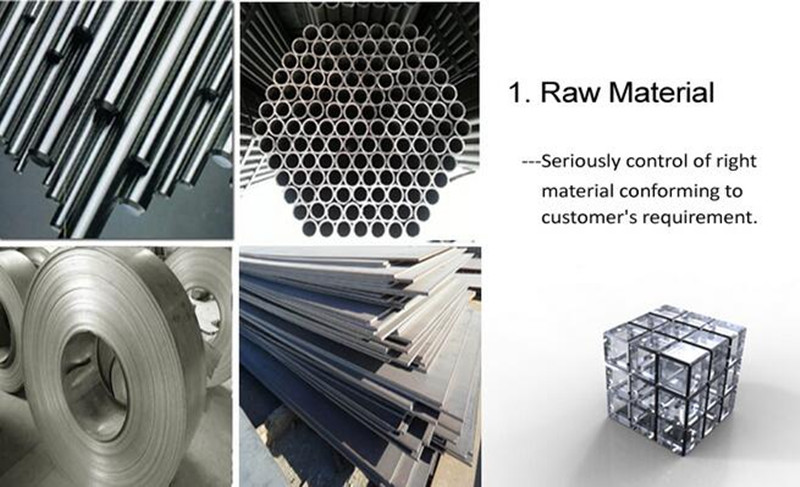

Materials: Aluminum, steel, stainless steel, brass, copper, low carbon steel, etc

Press range: 20-200 ton

Thickness: 0.25mm-6mm

Tolerance: 0.1mm

Inspection: 1st Piece Inspection, In-Process, Final

Production volume: From single piece prototypes to volume in the tens-of-millions of pieces per year.

Industry focus: Agriculture, Truck, automotive, electronics, medical, furniture, hardware, machinery, etc

Please CONTACT US today to see how we may help with your specialty metal stamping requirements.

Process