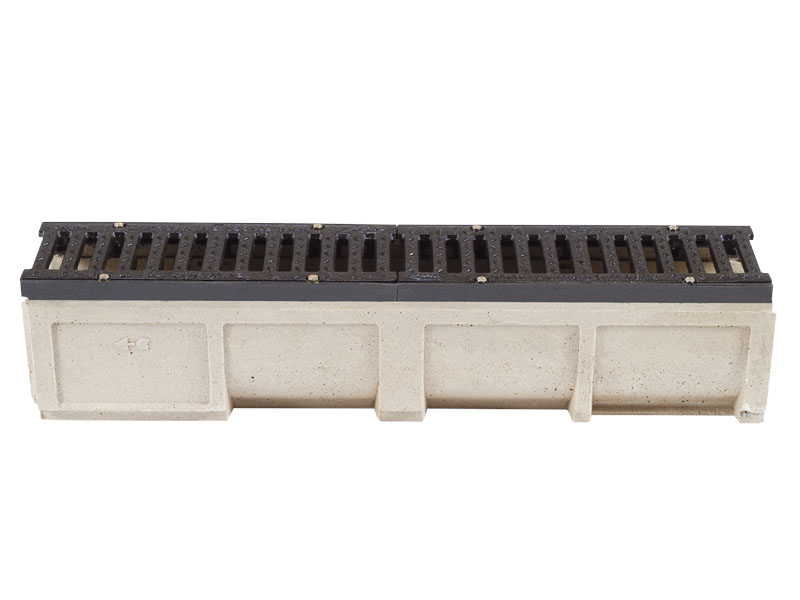

Effective drainage infrastructure is critical across industrial, commercial, and public sectors to prevent flooding, manage wastewater, and ensure operational safety. Among the various solutions available, the u channel grating system stands out for its efficiency and robustness. However, not all channel materials are created equal. Polyester concrete drainage channels represent a significant advancement, offering unparalleled durability, chemical resistance, and flow characteristics compared to traditional materials. This comprehensive guide delves into the technical aspects, manufacturing excellence, and diverse applications of these cutting-edge drainage solutions, providing insights for B2B decision-makers seeking long-term, high-performance investments.

The demand for high-performance drainage solutions has never been higher, driven by stricter environmental regulations, increasing extreme weather events, and the need for low-maintenance infrastructure. Traditional concrete or cast-iron channels often fall short in corrosive environments, heavy load areas, or where chemical resistance is paramount. This is precisely where the specialized properties of polyester concrete provide a decisive advantage. As a composite material, it offers superior strength-to-weight ratio, excellent hydraulic properties due to its smooth surface, and resistance to a vast array of aggressive substances, making it an ideal choice for complex industrial and municipal projects.

The production of polyester concrete drainage channels involves a sophisticated manufacturing process that ensures superior structural integrity and performance. Unlike traditional concrete, which uses cement as a binder, polyester concrete utilizes a resin binder (typically unsaturated polyester resin) mixed with mineral aggregates such as quartz sand and basalt. This mixture is then precisely formulated, vibrated to eliminate air voids, and cured under controlled conditions. The curing process involves a chemical reaction that polymerizes the resin, creating a dense, non-porous material with exceptionally high compressive and flexural strength. This meticulous approach to manufacturing guarantees the consistent quality and long service life expected from a leading channel grate factory.

Quality control is integrated at every stage, from raw material inspection to final product testing. Key manufacturing steps include:

Understanding the technical specifications of polyester concrete u channel grating is crucial for selecting the right product for specific applications. These channels are designed to meet stringent international standards for load-bearing capacity, hydraulic efficiency, and chemical resistance. Key parameters include:

| Parameter | Typical Value (Polyester Concrete) | Significance |

|---|---|---|

| Compressive Strength | ≥ 90 MPa (13,000 psi) | Indicates resistance to crushing; critical for heavy load applications (e.g., airports, industrial zones). |

| Flexural Strength | ≥ 25 MPa (3,600 psi) | Measures resistance to bending or breaking; important for long spans and dynamic loads. |

| Water Absorption | < 0.1% | Very low porosity prevents freeze-thaw damage and chemical penetration, enhancing durability. |

| Roughness Coefficient (Manning's 'n') | 0.009 - 0.010 | Extremely smooth surface minimizes flow resistance, leading to higher hydraulic efficiency and self-cleaning properties. |

| Chemical Resistance | Resistant to acids, alkalis, salts, oils, fuels | Crucial for industrial environments (e.g., petrochemical, chemical plants). |

| Temperature Resistance | -40°C to +100°C | Withstands wide temperature fluctuations without degradation. |

These parameters are instrumental in ensuring that the polyester concrete drainage channels perform optimally in demanding environments. For instance, the high compressive and flexural strengths allow for impressive load classes up to F900 (as per EN 1433), meaning these channels can withstand wheel loads of up to 90 tonnes, making them suitable for airport runways, port facilities, and heavy industrial areas. Furthermore, the extremely low water absorption and excellent chemical resistance significantly extend the service life, drastically reducing maintenance and replacement costs over decades.

The versatility and superior performance of polyester concrete drainage channels make them indispensable across a multitude of industries. From large-scale infrastructure projects to specialized industrial facilities, their robust design and chemical resistance offer significant advantages. Key application areas include:

In a recent project for a major chemical manufacturing facility, the implementation of our polyester concrete u channel grating systems resulted in a 40% reduction in maintenance costs over five years, primarily due to the channels' superior resistance to sulfuric acid spills. This long-term cost-effectiveness and operational reliability make them a preferred choice for project managers and engineers who prioritize total cost of ownership over initial expenditure. Compared to a standard concrete or even a polypropylene channel, polyester concrete offers a significantly longer lifespan in aggressive environments, reducing the need for costly replacements and downtime.

Recognizing that every project has unique requirements, leading channel grate factory specialize in providing tailored polyester concrete drainage solutions. This includes custom channel dimensions, various grate designs (e.g., slotted, mesh, ductile iron, stainless steel) to meet specific load classes and aesthetic needs, and specialized outlets or sumps. Our engineering team collaborates closely with clients from conceptual design to installation, ensuring optimal system performance. This bespoke approach allows for seamless integration into complex architectural and engineering plans, addressing challenges such as specific hydraulic capacities, unique site topography, or extreme load conditions.

Our expertise extends beyond standard product offerings. We provide comprehensive technical support, including hydraulic calculations, CAD drawings, and installation guidance. Whether it's a project requiring specific chemical resistance, a unique load profile, or integration with existing drainage networks, our ability to engineer custom polyester concrete solutions ensures that clients receive a system perfectly matched to their operational demands and environmental challenges. This commitment to customized solutions solidifies our position as a reliable partner in critical infrastructure development.

As a prominent china channel grate manufacturer, our commitment to quality is unwavering, backed by international certifications and rigorous testing protocols. We adhere to ISO 9001 quality management standards, ensuring consistent production quality and operational efficiency. Our polyester concrete drainage channels comply with European standard EN 1433, which specifies requirements for linear drainage channels for vehicular and pedestrian areas. This certification guarantees products meet stringent performance criteria for load-bearing capacity, durability, and hydraulic efficiency. Transparency in our testing data and material specifications builds trust with our global clientele.

We offer robust warranty programs and comprehensive after-sales support, reflecting our confidence in the longevity and performance of our polyester concrete channels. Our typical delivery cycle is efficient, designed to meet project timelines without compromising quality, with standard orders processed within 3-4 weeks and expedited options available for urgent requirements. Test reports, material safety data sheets, and installation guidelines are readily provided, empowering clients with all necessary information for informed decision-making and seamless project execution. This dedication to verifiable quality and customer support underpins our reputation as a trusted supplier of high-performance drainage solutions.

The polyester concrete drainage channel represents a pinnacle in modern drainage technology. Its superior material properties, combined with advanced manufacturing techniques, ensure a product that excels in durability, chemical resistance, and hydraulic performance. For B2B clients in demanding sectors like petrochemical, metallurgy, and heavy infrastructure, investing in these advanced u channel grating systems translates directly into reduced maintenance costs, extended operational life, and enhanced safety. As a dedicated channel grate factory, we are committed to providing innovative, high-quality, and customizable solutions that meet the evolving needs of global industries, ensuring reliable and efficient fluid management for decades to come.